Are you struggling to package corrosive disinfectants? Using the wrong equipment can lead to machine damage and safety hazards. You need a reliable solution that protects both your product and investment.

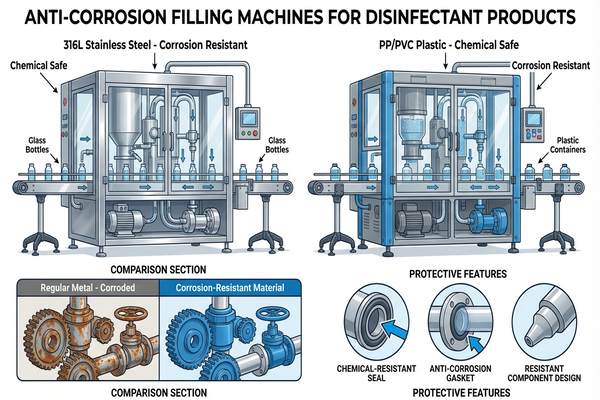

For filling disinfectants, you should always use an anti-corrosion filling machine1. These machines are built with materials like 316L stainless steel2 or special plastics (PP/PVC) that resist damage from corrosive chemicals, ensuring safety, product purity, and a longer lifespan for your equipment.

Choosing the right machine is a big decision. It’s not just about filling bottles; it's about setting up a safe and efficient production line that will last for years. I've seen many businesses make costly mistakes by overlooking the details. Let's break down what you really need to know to make the right choice, so you can feel confident in your packaging process.

Why is an anti-corrosion filling machine1 the best choice for disinfectants?

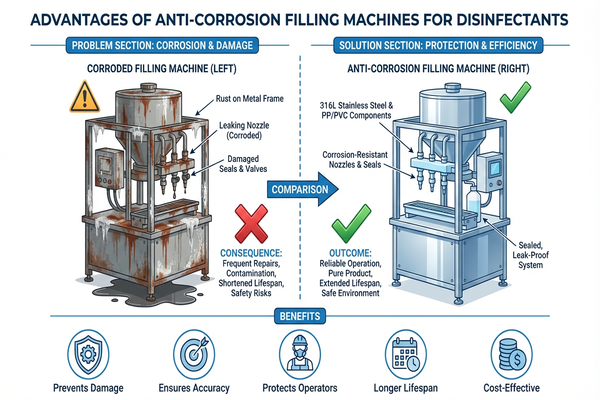

Worried that your standard filling machine will break down from harsh chemicals? Disinfectants can eat away at metal parts, causing leaks and costly failures. This puts your production and safety at risk.

An anti-corrosion filling machine1 is essential because disinfectants are often corrosive. Using a machine designed to handle these chemicals prevents damage, ensures accurate filling, and protects your operators. It's the safest and most cost-effective choice for long-term production.

Let's dive deeper into this. Many common disinfectants contain active ingredients like sodium hypochlorite3 (bleach), hydrogen peroxide4, or quaternary ammonium compounds5. These chemicals are highly reactive and can quickly corrode standard metals, including lower-grade stainless steel like 304. When I first started in this industry, I visited a facility that tried to use a standard water filler for a bleach-based cleaner. Within weeks, the nozzles were clogged, the seals were leaking, and rust was contaminating the product. This is why specialized materials are non-negotiable. An anti-corrosion machine uses materials specifically chosen for their chemical resistance6.

Here’s a simple breakdown of materials:

| Material Type | Used In | Why It Matters |

|---|---|---|

| 304 Stainless Steel | Standard Food/Beverage Fillers | Good for non-corrosive liquids but will rust with disinfectants. |

| 316L Stainless Steel | Anti-Corrosion Fillers | Contains molybdenum, which greatly increases resistance to chlorides and acids. |

| PP/PVC/PTFE | Wetted Parts, Tubing, Tanks | These plastics are chemically inert and will not react with or degrade from strong chemicals. |

By investing in a machine built with these materials, you are not just buying a filler. You are buying peace of mind, ensuring your production line runs smoothly without unexpected downtime or safety issues.

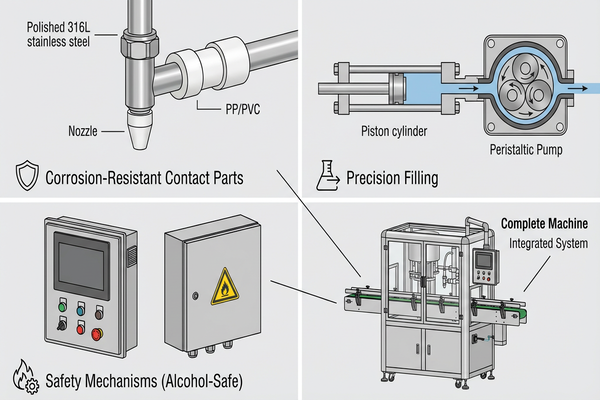

What specific features should you look for in a disinfectant filling machine?

Feeling overwhelmed by all the technical options for a filling machine? It's hard to know which features are "must-haves" and which are just expensive add-ons. You need clarity to choose a machine that fits your exact needs.

Focus on three key features: corrosion-resistant contact parts, an appropriate filling system (like a piston or peristaltic pump7), and safety mechanisms like explosion-proof components8 if you handle alcohol-based products. These features directly address the challenges of filling disinfectants.

When we talk about features, it's about matching the machine to your specific product. First, as we've discussed, all "wetted parts" — anything the disinfectant touches — must be made from resistant materials like 316L stainless steel2, titanium alloy, or non-metallic polymers like PP. This is your first line of defense. Second, consider the filling method. For thin, watery disinfectants, a gravity filler might work. But for thicker gels or liquids that foam, a piston filler9 or a servo-driven pump provides more control and accuracy, preventing spills and waste. A client of ours who produces an alcohol-based hand sanitizer gel found that a piston filler9 gave them the precision they needed to avoid foaming and get a consistent fill level every time. Finally, safety is paramount. If your disinfectant contains alcohol or other flammable solvents, you absolutely need explosion-proof motors and electronics. This is a certified safety standard (often referred to as ATEX or similar) that prevents a spark from igniting flammable vapors, a critical feature for protecting your facility and your team.

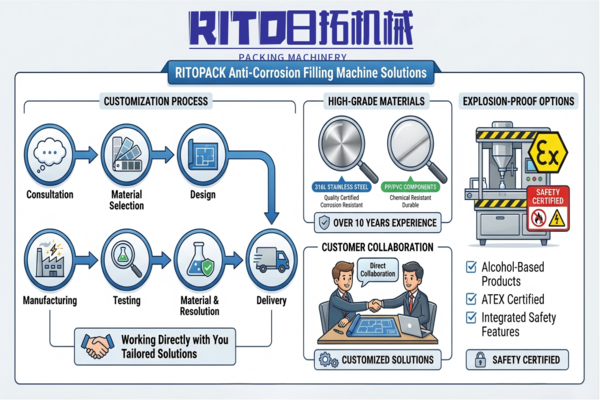

How does RITOPACK10 ensure its filling machines are safe for disinfectants?

Are you concerned about whether a manufacturer truly understands the risks of handling your specific chemical products? Many companies sell generic machines, but you need a partner who can provide a solution truly tailored to your needs.

At RITOPACK10, we leverage over a decade of experience to build customized anti-corrosion filling machines11](1s">https://www.tompacks.com/new_detail/How-Bleach-Filling-Machines-Operate-and-Their-Uses-in-Industry.html)1s. We use only high-grade materials like 316L stainless steel2, offer explosion-proof options, and work directly with you to ensure the machine is perfect for your disinfectant.

Our approach is built on a foundation of deep technical expertise and a customer-centric mindset. Our R&D team, with over 20 years of experience in packaging machinery, doesn't just build standard equipment. We start by understanding your product's chemical makeup. When a new client came to us looking to bottle a highly acidic industrial cleaner, we didn't just recommend a standard anti-corrosion model. We requested their product's Material Safety Data Sheet (MSDS)12 to analyze its components. Based on that, we recommended a machine with not only 316L stainless steel2 contact parts but also specialized PTFE seals and tubing to guarantee long-term resistance. This is what we mean by "Exclusive customization." We don't believe in one-size-fits-all. Our commitment extends beyond the sale with lifetime service and support, ensuring your investment is protected for years to come. This is the RITOPACK10 difference—we don't just sell you a machine; we deliver a complete, reliable, and safe packaging solution.

Conclusion

In summary, choosing the right filling machine for disinfectants is simple: always opt for an anti-corrosion model to ensure safety, reliability, and long-term value for your production line.

Explore the advantages of anti-corrosion filling machines to ensure safety and efficiency in your production line. ↩

Learn why 316L stainless steel is essential for handling corrosive chemicals safely and effectively. ↩

Discover the properties and applications of sodium hypochlorite in disinfectant formulations. ↩

Find out how hydrogen peroxide is utilized in cleaning products and its effectiveness as a disinfectant. ↩

Understand the significance of quaternary ammonium compounds in disinfectant formulations. ↩

Learn about materials with superior chemical resistance to enhance safety and longevity in equipment. ↩

Discover the functionality of peristaltic pumps and their benefits in precise filling processes. ↩

Learn about explosion-proof components and their critical role in ensuring safety in chemical handling. ↩

Explore the mechanics of piston fillers and their advantages for filling thick liquids accurately. ↩

Discover how RITOPACK's expertise and customization set them apart in the filling machine industry. ↩

Explore the benefits of tailored filling machines designed specifically for your chemical products. ↩

Understand the importance of MSDS in ensuring safe handling of chemical products. ↩