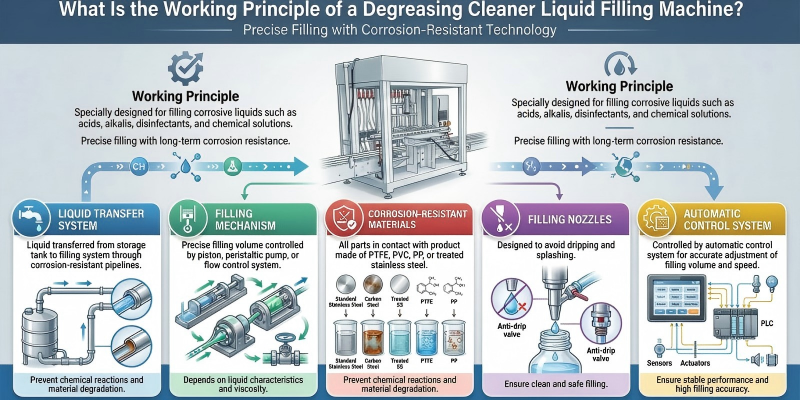

Struggling with messy, inaccurate fills for your corrosive degreasing cleaners1? This can damage equipment and waste product, hurting your production line2. A specialized filling machine3 is the answer.

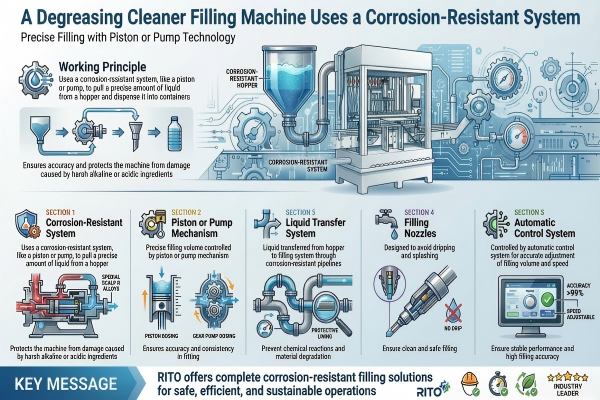

A degreasing cleaner filling machine3 uses a corrosion-resistant4 system, like a piston or pump, to pull a precise amount of liquid from a hopper and dispense it into containers. This method ensures accuracy and protects the machine from damage caused by harsh alkaline or acidic ingredients.

That's the basic idea, but the real magic is in the details. The right machine depends entirely on your specific product. The viscosity5 and corrosive properties of the cleaner are the two most important factors we need to consider. To truly understand how it works, we have to look at how these challenges are solved. Let's dive deeper into how we select the perfect setup for these tricky liquids.

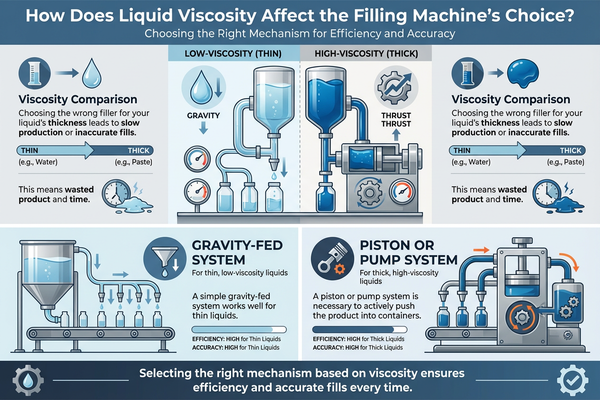

How Does Liquid Viscosity Affect the Filling Machine's Choice?

Choosing the wrong filler for your liquid's thickness leads to slow production or inaccurate fills. This means wasted product and time. Selecting the right mechanism based on viscosity5 ensures efficiency.

For thin, low-viscosity5 liquids, a simple gravity-fed system works well. But for thicker, more viscous degreasers, a piston or pump system is necessary to actively push the product into containers for an accurate and consistent fill every single time.

Viscosity is just a simple word for how thick a liquid is. Water is thin, and honey is thick. Degreasing cleaners can be anywhere in between. This property completely changes how we approach filling. I once worked with a client who was using a gravity filler for a slightly thicker degreaser formula. Their fill volumes were all over the place because the liquid was too thick to flow consistently. We had to help them switch to a piston filler6, which solved the problem immediately.

Gravity Fillers for Thin Liquids

Gravity fillers are the simplest type. The machine has a holding tank located above the filling nozzles. When it's time to fill, a valve opens, and the liquid flows down into the bottles using just the force of gravity. This method is great for very thin, free-flowing liquids like water-based cleaners. It's cost-effective and easy to maintain. However, it's not suitable for thicker products or liquids that tend to foam, as the flow rate can be slow and hard to control precisely.

Piston and Pump Fillers for Thicker Liquids

For medium to high-viscosity5 degreasers, you need a machine that takes active control. This is where piston and pump fillers7 come in.

- Piston Fillers: A piston filler6 works like a giant syringe. The piston pulls back, drawing a specific volume of product into a cylinder. Then, it pushes forward, dispensing that exact amount into the container. This method is incredibly accurate and is my go-to recommendation for most degreasers, gels, and creams.

- Pump Fillers: Pump fillers use a pump (like a gear, lobe, or peristaltic pump) to move the liquid from a tank to the nozzles. They are very versatile and can handle a huge range of viscosities, from thin liquids to thick pastes. We can also precisely control the pump speed, which helps manage foaming.

Here is a simple table to show the differences.

| Filler Type | Ideal Viscosity | Working Principle | Best For... |

|---|---|---|---|

| Gravity Filler | Low (Water-like) | Liquid flows via gravity from a tank above the bottles. | Free-flowing, non-foaming liquids. |

| Piston Filler | Medium to High | A piston draws and dispenses a precise volume of liquid. | Gels, creams, and most degreasers. |

| Pump Filler | All Viscosities | A pump moves the product from a tank to the container. | Maximum versatility for multiple products. |

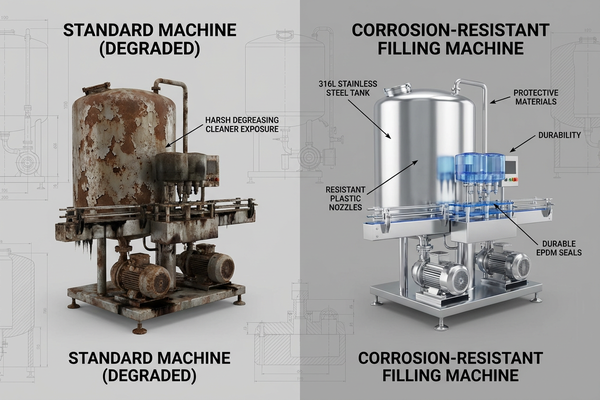

How Do You Handle the Corrosive Nature of Degreasing Cleaners?

Corrosive cleaners can eat away at standard machines, leading to costly breakdowns and contamination. This downtime stops your production line2. Using machines made from the right materials is the key.

To handle corrosive degreasers, filling machine3s are built with resistant materials like 316L stainless steel8 or specific plastics. All parts that touch the liquid, including the tank, nozzles, and seals, must be non-reactive to prevent corrosion and ensure product purity.

Degreasing cleaners often contain ingredients like sodium hydroxide9 or phosphoric acid10. These chemicals are great for cleaning but are very aggressive toward metals. Using a standard machine made from 304 stainless steel is a recipe for disaster. I've seen it happen. The machine starts to corrode, little metal particles get into the product, and eventually, the machine fails completely. That’s why we must pay close attention to every single material that will touch the product. It’s not just about the big parts; it's about everything.

The Importance of Material Selection

The first line of defense is choosing the right material. The industry standard for most chemical applications is 316L stainless steel8. It contains an element called molybdenum, which gives it excellent resistance to the acids and alkalis found in degreasers. For extremely aggressive chemicals, we might even use special plastics like PVC or PE for the liquid path11. In rare cases with very strong acids, we have even built machines with titanium contact parts. It’s expensive, but it’s a permanent solution.

Design Features for Safety and Longevity

Beyond the main material, the smaller components are just as critical.

- Seals and Gaskets: The o-rings and seals that prevent leaks must also be chemically resistant. We often use materials like Viton or Teflon (PTFE) because they hold up much better than standard rubber. A failed seal can cause a leak, which is a safety hazard and can damage the rest of the machine.

- Clean-in-Place (CIP) Systems: Manually cleaning a machine used for corrosive liquids is dangerous and time-consuming. That's why many of our machines are designed with Clean-in-Place systems. This allows you to run cleaning cycles with water or neutralizing agents automatically, without having to take the machine apart. It’s safer for your team and gets you back to production faster.

Here is a quick guide to the materials we use.

| Material | Resistance Level | Common Use Case | Notes |

|---|---|---|---|

| 304 Stainless Steel | Low | Non-corrosive foods, water. | Not suitable for degreasing cleaners. |

| 316L Stainless Steel | High | Most degreasers, chemicals, pharmaceuticals. | The industry standard for reliability. |

| PVC/PE Plastics | Very High | Highly acidic or alkaline solutions. | Cost-effective, but may have temperature limits. |

| Viton/Teflon | Very High | Seals, gaskets, and tubing. | Essential for preventing leaks with corrosive liquids. |

Conclusion

In short, filling degreasers requires a corrosion-resistant4 machine, often a piston filler6, chosen based on the liquid's viscosity5. This ensures accuracy, safety, and a long machine life.

Explore this resource to understand how to safely manage corrosive cleaners and protect your equipment. ↩

Learn how the right filling machine can enhance overall production efficiency and reduce waste. ↩

Learn about various filling machines and their specific applications for degreasing cleaners. ↩

Explore materials that ensure longevity and safety in filling machines for corrosive liquids. ↩

Discover the impact of viscosity on filling processes and how to choose the right machine. ↩

Find out why piston fillers are recommended for accurate filling of degreasers and similar products. ↩

Understand the versatility of pump fillers and how they can handle various liquid types. ↩

Learn about the properties of 316L stainless steel and its importance in corrosive environments. ↩

Explore the corrosive effects of sodium hydroxide and how to mitigate them in machinery. ↩

Understand the challenges posed by phosphoric acid and how to protect your equipment. ↩

Discover the best materials for the liquid path to ensure safety and product integrity. ↩