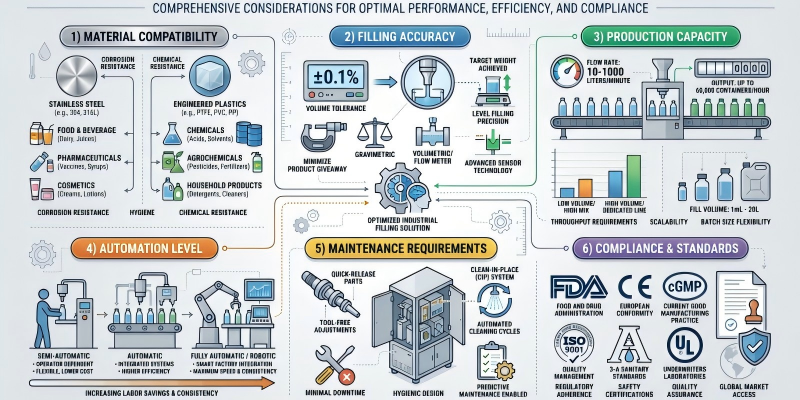

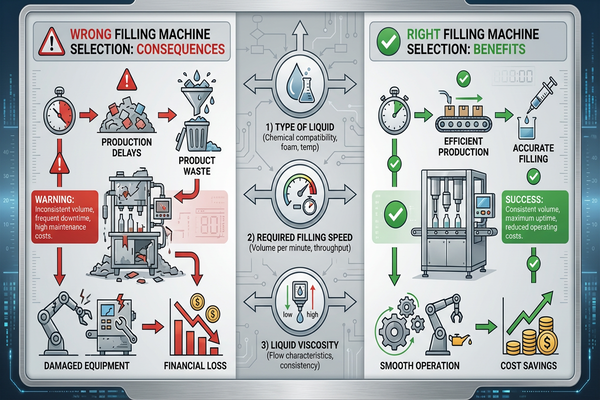

Choosing the wrong filling machine1 can cause production delays2 and product waste3. This mistake costs you money and damages your reputation. Understanding key factors ensures you make the right choice.

The most important factors are the type of liquid, your required filling speed4, and the liquid's viscosity. Matching these three elements to the machine's capabilities is essential for an efficient and accurate production line. Considering these will prevent costly errors and downtime.

It seems simple on the surface, but each of these factors has details you just can't afford to ignore. I learned this the hard way early in my career when a client's production line failed because of a simple oversight. We had to fix it, fast. Let's break down each point so you can avoid the same headaches. Getting this right from the start saves you time, money, and a lot of stress. So, let's dive into the first, and maybe most important, factor.

How does the type of liquid affect your choice of a filling machine1?

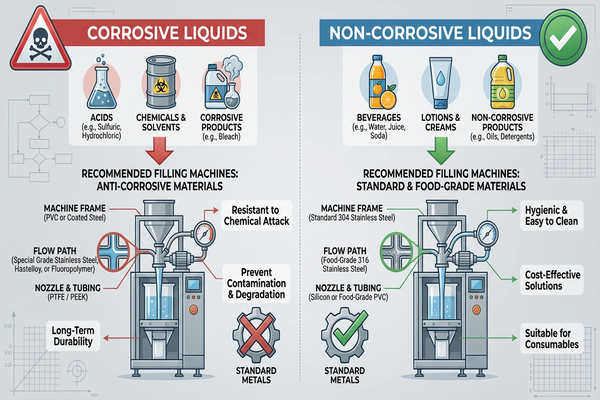

Using the wrong material for your machine can lead to corrosion and product contamination. This could ruin your product batches and destroy your expensive equipment over time.

Corrosive liquids, like certain chemicals or acidic products, require machines made from anti-corrosive materials like PVC or specific grades of stainless steel. For non-corrosive products like beverages or lotions, standard stainless steel is fine, but food-grade 316 stainless steel is highly recommended for safety and hygiene.

When we talk about the type of liquid, we are really talking about its chemical properties. This is the foundation of your decision. I once worked with a startup in the cleaning supplies industry5. They almost purchased a standard filler for a highly corrosive bleach-based product. We stopped them just in time. That machine would have been damaged within months. We helped them select a machine built with corrosion-resistant materials, and it's still running perfectly today.

Corrosive vs. Non-Corrosive Liquids

The first question you must ask is: is my product corrosive?

- Corrosive Liquids: These include acids, bleach, certain cleaning agents, and high-salt solutions. They will eat away at standard metals. For these, you need a machine constructed from materials like PVC, or for higher-end applications, titanium.

- Non-Corrosive Liquids: This category includes water, juice, milk, oils, and lotions. These are much easier to handle.

Material Selection is Key

Your choice of material directly impacts your machine's lifespan and your product's purity. Here's a simple breakdown:

| Material | Best For | Why? |

|---|---|---|

| 304 Stainless Steel6 | General non-corrosive liquids7s](https://iconprocon.com/blog-post/understanding-chemical-compatibility-and-materials-for-corrosive-liquids/)%%%FOOTNOTE_REF_8%%%, oils, lotions | Good durability and resistance for most standard applications. |

| 316 Stainless Steel9 | Food, beverages, pharmaceuticals | Higher corrosion resistance, especially against salts and acids. The industry standard for hygiene. |

| PVC / Plastic | Strong acids and bleach | Completely resistant to corrosion from harsh chemicals, but less durable. |

At RITO PACK10, we always start our consultation by analyzing the customer's product. It’s a non-negotiable first step. Ensuring the contact parts are made of the right material, like 316 stainless steel for a beverage company, isn't just a recommendation; it's a guarantee of safety and quality.

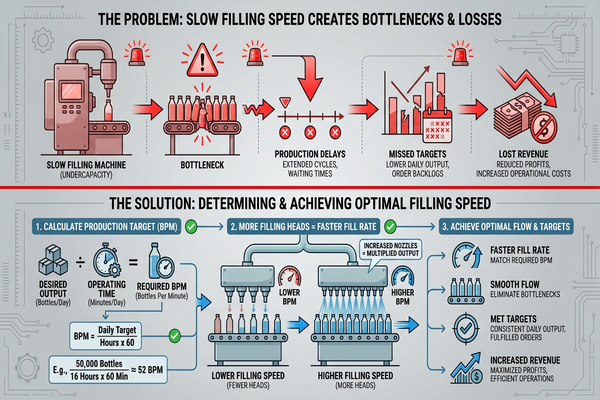

How do you determine the right filling speed4 for your production line?

Your filling machine1 is too slow, creating a bottleneck that holds up your entire operation. This means you are missing production targets11, delaying shipments, and losing potential revenue.

You determine the right filling speed4 by calculating your production target in "bottles per minute12" (BPM). This target then dictates how many filling heads13 or nozzles your machine needs. More heads mean a faster fill rate, allowing you to meet higher demand.

Speed isn't just about going fast; it's about being efficient. A machine that's too fast for the rest of your line (capping, labeling) is just as bad as one that's too slow. It creates chaos. The goal is to create a smooth, balanced flow from start to finish. I've seen companies buy the fastest machine available, only to run it at half-speed because their other equipment couldn't keep up. That's a waste of investment. You need to think about your entire process.

Calculating Your Production Needs

Start with a simple question: How many units do I need to produce per hour or per day? Let's do some quick math. If you need to produce 24,000 bottles in an 8-hour shift, you'll need a machine that can handle:

24,000 bottles / 8 hours = 3,000 bottles per hour

3,000 BPH / 60 minutes = 50 [bottles per minute](https://www.ritopackmachinery.com/)12 (BPM)

Your target speed is 50 BPM. Now you can look for a machine that meets this requirement.

The Role of Filling Heads

The number of filling heads13 (or nozzles) on a machine is the primary factor determining its speed.

- 2-4 Heads: Suitable for startups or small-batch production.

- 6-8 Heads: A great middle-ground for growing businesses.

- 10+ Heads: Designed for large-scale industrial operations with high-volume output.

A machine with more heads can fill more bottles at the same time, dramatically increasing your BPM.

Balancing Speed, Cost, and Future Growth

It's tempting to buy a machine that only meets your current needs. But I always advise my clients to think about the future. If you plan to grow, investing in a machine with more heads than you need right now can be a smart move. For example, buying an 8-head filler and only using 6 heads initially gives you room to increase production without buying a whole new machine. At RITO PACK10, we specialize in scalable solutions. We design filling line14s that can grow with your business, ensuring your initial investment continues to pay off for years to come.

Why is liquid viscosity15 the most critical factor for filling accuracy16?

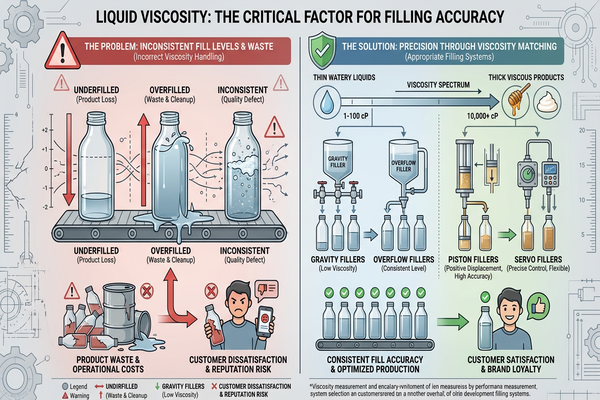

You're constantly dealing with inconsistent fill levels. Some bottles are overfilled, while others are underfilled. This leads to product waste3, unhappy customers, and potential compliance issues.

Viscosity, or a liquid's thickness, determines how it flows. Thin, watery liquids are handled well by gravity or overflow fillers. Thick, viscous products like honey or cream require a positive displacement system17, like a piston or servo filler, to ensure accurate, drip-free filling.

Viscosity is where the real engineering comes into play. If you try to use a simple gravity filler for a thick gel, you’ll be waiting forever for it to fill, and the results will be a mess. On the other hand, using a powerful piston filler for a water-thin liquid can cause splashing and inaccuracy. I’ll never forget a new client who came to us because their previous machine, a gravity filler, was splashing their expensive serum everywhere. We switched them to a servo-driven piston filler18 from our lineup, and the problem vanished overnight. They cut their product waste3 by over 15%.

Matching the Filling System to Your Liquid's Flow

The type of filling mechanism you choose must be compatible with your product’s viscosity. It’s the difference between a clean, efficient process and a slow, messy one.

The Main Types of Filling Systems

| Filling System | Best For Viscosity | How It Works | Common Products |

|---|---|---|---|

| Gravity Filler | Very Low (Watery) | Liquid flows from a tank above the bottles, using gravity. Simple and cost-effective. | Water, thin juices, alcohol, window cleaner |

| Overflow Filler | Low to Medium | Fills to a specific level in the bottle, ideal for transparent containers. | Wine, sauces, cleaning supplies |

| Piston Filler | Medium to High | A piston pulls product into a cylinder and then pushes it out into the container. Very accurate. | Lotions, creams, gels, sauces, peanut butter |

| Servo Piston Filler | All Viscosities | An advanced piston filler controlled by a servo motor. Offers ultimate control and precision. | High-value cosmetics, pharmaceuticals, thick pastes |

The RITO PACK10 Advantage: Servo Technology

This is where our expertise at RITO PACK10 truly shines. While standard piston fillers are great, our servo-driven piston filling machine1s offer a level of control that is unmatched. The servo motor precisely controls the piston's movement, allowing for incredibly accurate fill volumes, regardless of changes in product viscosity or temperature. You can program fill speeds, prevent dripping with custom nozzle movements, and store recipes for different products. This technology minimizes waste and guarantees a consistent, high-quality product every single time. It's the ultimate solution for anyone who cannot compromise on accuracy.

Conclusion

Choosing the right filler comes down to your liquid's type, your speed needs, and its viscosity. Get these right, and you'll build a reliable, efficient production line.

Explore this link to understand the various filling machines available and how to choose the right one for your needs. ↩

Learn effective strategies to reduce production delays and improve efficiency in your operations. ↩

Discover the common causes of product waste and how to prevent them in your production process. ↩

Find out how to optimize filling speed for your production line and avoid bottlenecks. ↩

Learn about the unique challenges faced by the cleaning supplies industry in filling operations. ↩

Discover the advantages of 304 stainless steel for various applications in manufacturing. ↩

Learn about non-corrosive liquids and their implications for filling machine selection. ↩

Explore the best materials for machines that handle corrosive liquids to ensure safety and longevity. ↩

Explore why 316 stainless steel is the industry standard for food safety and hygiene. ↩

Explore RITO PACK's services to find tailored filling solutions for your business needs. ↩

Learn how to set realistic production targets to optimize your manufacturing efficiency. ↩

Find out how to calculate BPM to ensure your filling machine meets production targets. ↩

Understand the role of filling heads in machine speed and how to choose the right number for your needs. ↩

Understand the essential components of a filling line to enhance your production process. ↩

Understanding viscosity is crucial for accurate filling; explore this resource for in-depth insights. ↩

Discover the key factors that influence filling accuracy and how to achieve consistent results. ↩

Learn about positive displacement systems and their importance for accurate filling of viscous products. ↩

Explore the benefits of servo-driven piston fillers for high-precision filling applications. ↩