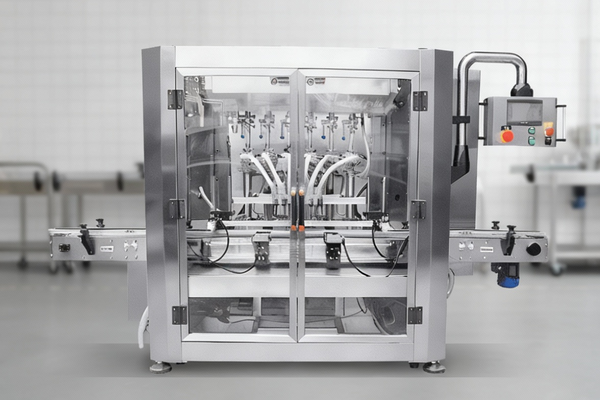

Handling corrosive chemicals1 is risky, and the wrong filling machine2 can cause leaks, damage, and hazards. This wastes product and money while threatening your workers and equipment.

Choosing the right corrosive liquid filling machine2 involves understanding your product's acidity and viscosity3, selecting anti-corrosion materials4 like PTFE (Teflon)5, and evaluating accuracy, automation, and safety features6. A reliable supplier should offer customization7 and pre-delivery testing to ensure stable performance.

I've seen firsthand how a poorly chosen machine can bring a production line8 to a halt. The initial answer gives you a great starting point, but there's more to consider to make the right investment. Let's break down the key factors you need to evaluate to find a machine that is not only efficient but also safe and durable for the long run.

What material is best for handling corrosive liquids?

Choosing the wrong material for your filling machine2 is a costly mistake. Standard metals will corrode quickly, causing machine failure, contamination, and expensive downtime. You need materials specifically designed to resist harsh chemicals.

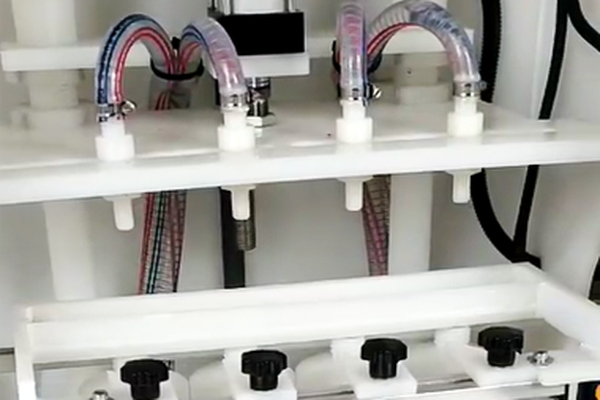

PTFE, commonly known as Teflon, is the gold standard for handling corrosive liquids. Its non-reactive, durable nature makes it ideal for parts that contact the product. This prevents corrosion and ensures the machine's longevity and your product's purity.

When you're dealing with acids, alkalis, or strong detergents, the material of your filling machine2's contact parts is non-negotiable. While stainless steel is common in many industries, even high-grade 316L stainless steel can degrade when exposed to certain aggressive chemicals over time. This is where specialized polymers come into play. At RITO9, we build our corrosive liquid filling machine2s with high-quality PTFE10E (Teflon) for all components that touch the product. This material is inert, meaning it won't react with your chemicals, preventing both machine damage and product contamination.

Here’s a quick comparison of common materials:

| Material | Corrosion Resistance | Best Use Case |

|---|---|---|

| Stainless Steel 304 | Low | Non-corrosive liquids, food products |

| Stainless Steel 316L | Moderate | Mildly corrosive liquids, pharmaceuticals |

| PTFE (Teflon)5 | Excellent | Highly corrosive acids, alkalis, bleach |

| Titanium | Excellent | Specialized, high-cost applications |

By using Teflon, we ensure our machines provide a long service life and safe operation, giving you peace of mind.

How does product viscosity affect your choice of filling machine2?

Are you struggling to fill thick, viscous chemicals accurately? Using the wrong filling mechanism can cause inconsistent fills, slow production speeds, and messy, wasteful spills. Matching the filling technology to your product's viscosity is key.

Product viscosity determines the best filling method. Low-viscosity liquids like water work well with gravity fillers11. However, high-viscosity products like gels or thick detergents require a piston filler or pump filler to ensure accurate and consistent dosing.

The "thickness" or flow resistance of your liquid is a critical factor. A machine designed for thin liquids will struggle to handle a thick gel, and vice versa. That’s why understanding the different filling technologies is so important for making the right choice.

Piston Fillers for High Viscosity

Piston fillers are the workhorses for thick, viscous products. They operate like a large syringe, pulling a precise volume of product into a cylinder and then pushing it out into the container. This method provides extremely accurate fills regardless of the product's thickness. It’s perfect for detergents, lotions, and thick chemical agents.

Gravity/Overflow Fillers for Low Viscosity

For thin, free-flowing liquids like acidic cleaners or solvents, gravity or overflow fillers are a simple and effective solution. They fill containers to a specific level rather than by a specific volume, which is great for transparent containers where a consistent appearance is important. They rely on gravity, so they are not suitable for thicker products that don't flow easily.

At RITO9, our R&D team has over 20 years of experience in packaging machinery12. We analyze our clients' product samples to recommend the perfect filling mechanism, ensuring you get optimal performance and accuracy for your specific chemical.

What safety features6 are essential for a corrosive liquid filler?

Worried about the safety of your operators when handling corrosive chemicals1? Spills, splashes, and fumes can cause serious injuries and violate safety regulations, leading to huge liabilities for your business.

Essential safety features6 include a fully enclosed design to contain fumes, drip-proof nozzles to prevent spills, and emergency stop buttons13. Also, look for machines with robust seals14 and materials like Teflon that won't degrade and cause dangerous leaks.

When working with corrosive materials, you can't afford to compromise on safety. A well-designed machine protects not only your product but, more importantly, your people. I always tell my clients to think of safety features6 as an investment, not a cost. A single accident can be far more expensive than the machine itself. Based on our experience, we've found that a combination of features creates the safest possible operating environment.

Here are the safety features6 we consider non-negotiable:

| Safety Feature | Function |

|---|---|

| Full Enclosure | Contains splashes and harmful fumes away from the operator. |

| Drip-Proof Nozzles | Prevents product from dripping after a fill, keeping the work area clean and safe. |

| Emergency Stop (E-Stop) | Allows anyone to immediately shut down the machine in case of a problem. |

| Level Sensors | Prevents containers from overfilling, avoiding spills and product waste. |

| Robust PTFE Seals | Ensures a tight seal on all connections to prevent hazardous leaks from developing over time. |

These elements work together to minimize risks. As a national high-tech enterprise, RITO9 is committed to building equipment that meets high safety standards, so your team can operate it with confidence.

Why is supplier customization7 and support so important?

Buying an off-the-shelf machine seems easy, but what if it doesn't fit your needs? You could end up with a machine that is inefficient, incompatible with your containers, or simply unable to handle your specific product.

Customization ensures the filling machine2 perfectly matches your product, containers, and production goals. A reliable supplier will analyze your samples, tailor the machine's components, and provide testing before delivery15 for guaranteed performance and smooth integration.

Every production line8 is unique. Your containers might have a special shape, your liquid might have a unique viscosity, or you may need to integrate the filler with an existing capper and labeler. This is where a one-size-fits-all approach fails. I remember a client who bought a standard machine online, only to find it couldn't handle their bottle's narrow opening, causing constant spills and downtime.

A good supplier acts as a partner. At RITO9, we leverage our 11 years of industry experience and strong R&D capabilities to offer professional, customized solutions. Our process involves:

- Analyzing your product samples to understand their properties.

- Matching the machine to your specific container types and sizes.

- Adjusting settings for your desired fill volume and production speed.

- Testing the machine with your products and containers before it ever leaves our factory.

As a company with over 10 patents and customers in more than 40 countries, we understand the importance of getting it right. We also provide lifetime maintenance services and free software upgrades, ensuring your investment continues to create value for years to come.

Conclusion

Choosing the right corrosive liquid filler means looking at materials, viscosity needs, safety, and supplier support. This ensures a safe, efficient, and durable solution for your chemical packaging line.

Understanding the risks associated with corrosive chemicals is crucial for safety and compliance in any industry. ↩

Choosing the right filling machine is essential for efficiency and safety in handling corrosive liquids. ↩

Understanding these properties helps in selecting the right filling technology for your products. ↩

Exploring anti-corrosion materials can enhance the longevity and safety of your filling equipment. ↩

PTFE is known for its excellent chemical resistance, making it ideal for corrosive applications. ↩

Safety features are critical to protect operators and ensure compliance with safety regulations. ↩

Customization ensures that the filling machine meets specific production needs and enhances efficiency. ↩

Optimizing your production line can enhance efficiency and reduce downtime in chemical handling. ↩

Explore RITO's expertise in customized filling solutions, ensuring safety and efficiency for your specific chemical needs. ↩

High-quality PTFE offers superior resistance to chemicals, ensuring safety and longevity in use. ↩

Gravity fillers are effective for thin liquids, and understanding their operation can improve filling efficiency. ↩

Staying updated on trends in packaging machinery can help you make informed investment decisions. ↩

Emergency stop buttons are crucial for ensuring operator safety in case of machine malfunctions. ↩

Robust seals prevent leaks and ensure safe operation, making them vital for corrosive applications. ↩

Testing ensures that the machine performs as expected, reducing the risk of operational issues. ↩