How Do Injection Molding Machines Create Plastic Flowers?

The crafting of plastic flowers is surprisingly complex and challenging.

Injection molding machines create plastic flowers through a precise process that involves multiple steps, including cooling, color mixing, and molding. Understanding these steps can help manufacturers achieve better results and higher quality products.

Creating plastic flowers isn't just about pressing plastic into shapes. It's a detailed process that requires skill and the right machinery. Many think that any injection molding machine can handle this task, but that's far from the truth. Only machines with high precision can deliver the quality needed.

LOOP START

What Makes Creating Plastic Flowers So Difficult?

The process to create plastic flowers is not as straightforward as it seems. The cold cooling phase is among the most challenging parts.

The cooling process1 is critical. If not done correctly, the flowers can shrink or lose their shape. This often depends on the machine's precision2 and the environment in which it's operated.

When I first worked with a customer from Pakistan to produce plastic flowers, I quickly learned how tricky this process could be. During our early attempts, we faced significant issues with "shrinkage3" after cooling. The plastic flowers lost their desired shape. Fortunately, the customer appreciated the unique look, which led to an unexpected success.

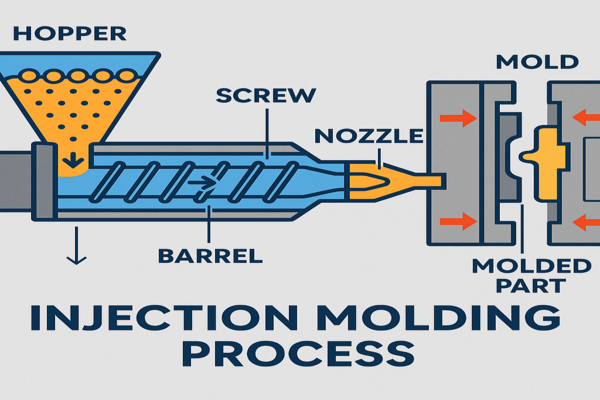

To create plastic flowers, machines go through several steps. Here’s a breakdown of the key stages:

| Step | Description |

|---|---|

| Molding | The plastic is heated and injected into the flower-shaped mold4. |

| Cooling | The plastic needs to cool down slowly to maintain its shape. |

| Coloring | Colorants are added5, which requires stopping the machine to mix the colors. |

The cooling phase is not where the challenges stop. Deciding when to add color is crucial. It's not just a matter of mixing it in; it requires the machine to pause, opening the mold, and risking inconsistencies while cooling. This complexity often leads to variations in the final product.

In regions like Fujian and around Shanghai, manufacturers have the expertise and equipment to create high-quality plastic flowers. However, machines from areas like Hebei often lack the necessary precision. This can lead to problems like poor quality and a lack of detailed designs6.

LOOP END

Conclusion

Creating plastic flowers involves a complex process requiring precision, skill, and the right machinery for successful results.

Discover how proper cooling techniques prevent shrinkage and shape loss, ensuring your plastic products maintain their intended design and quality. ↩

Understand the technical specifications that separate premium injection molding equipment from basic machines for superior product quality and consistency. ↩

Learn the science behind plastic shrinkage during cooling and explore proven methods to minimize this common manufacturing defect in your production. ↩

Explore the intricate world of mold design for detailed shapes and understand how precision tooling creates beautiful, consistent plastic flower products. ↩

Master the timing and techniques for color mixing in injection molding to achieve vibrant, uniform colors without compromising production efficiency. ↩

Unlock the secrets to producing complex, fine-detailed plastic items through advanced molding techniques and equipment capabilities for premium results. ↩