Product Overview

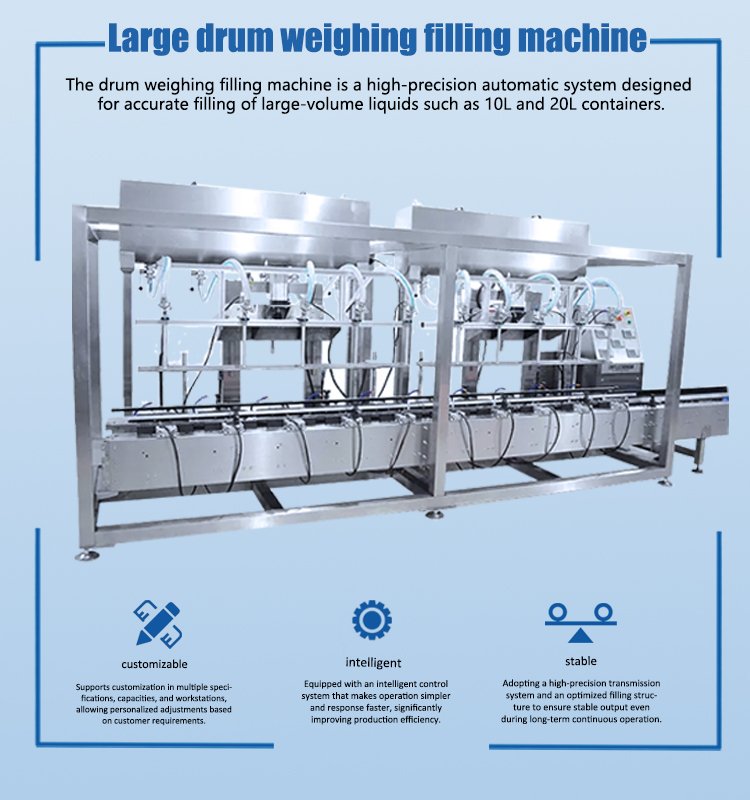

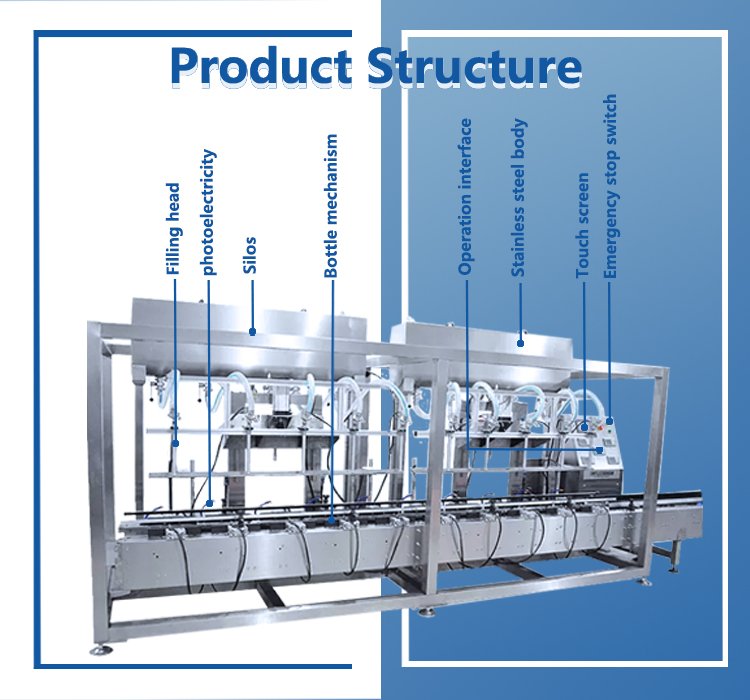

The Large Drum Weighing Filling Machine is a high-precision filling solution designed specifically for large-capacity containers up to 30 liters. It adopts an advanced weighing-based filling system, using real-time weight feedback to ensure accurate and consistent filling results.

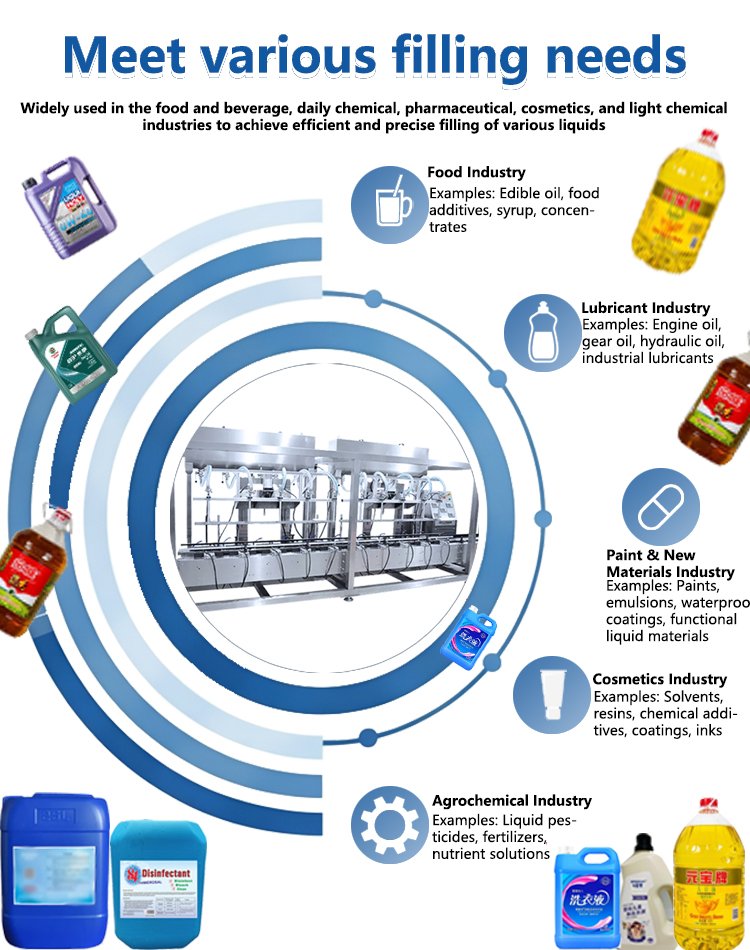

This machine is ideal for liquid products where weight accuracy, stability, and product value control are critical. It is widely used in chemical, lubricant, food, agrochemical, and related industries for medium-volume drum filling applications.

Key Features

-

High-Precision Weighing Filling System

Equipped with high-sensitivity load cells for real-time weight monitoring and automatic feedback control. -

Automatic Weight Measurement & Correction

The system automatically adjusts filling speed and volume based on weighing feedback to ensure consistent accuracy. -

Stable Filling Performance

Filling accuracy is not affected by liquid viscosity, temperature, or density changes. -

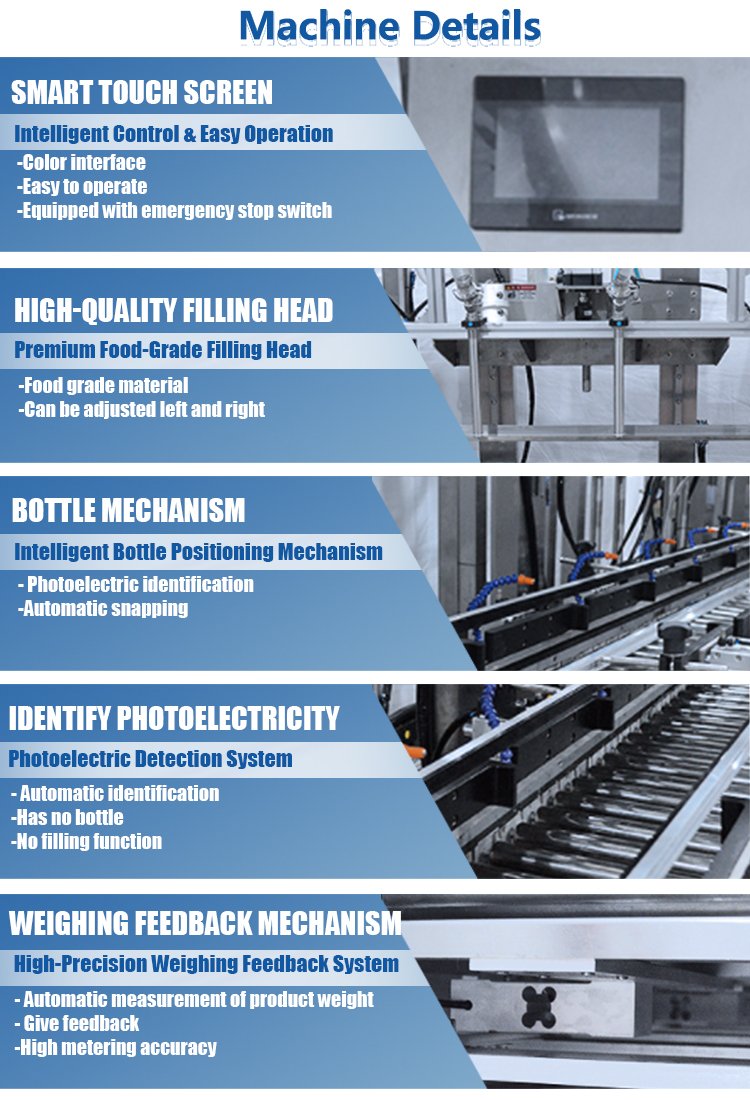

PLC + Touchscreen Control

User-friendly HMI allows easy setting of target weight, filling speed, and recipe storage. -

Anti-Drip Filling Nozzle

Special nozzle design prevents dripping and material waste, ensuring a clean filling process. -

Compact & Robust Structure

Designed for large drums up to 30L while maintaining a compact footprint and stable operation. -

Durable & Hygienic Construction

Made of high-quality stainless steel, suitable for industrial and food-grade applications.

Key Selling Points

-

High weighing accuracy for precise filling of valuable liquids

-

Ideal for 10–30L drums, filling gap between small bottles and large barrels

-

Reduced product loss through automatic weight feedback control

-

Simple operation & low labor requirement

-

Reliable and repeatable performance for continuous production

-

Customizable configurations based on product characteristics

Applicable Industries & Examples

-

Chemical Industry

Solvents, chemical additives, liquid raw materials, cleaning agents -

Lubricant Industry

Engine oil, hydraulic oil, gear oil, lubricating fluids -

Food Industry

Edible oil, food additives, syrup, flavor concentrates -

Agrochemical Industry

Liquid fertilizers, pesticide solutions, nutrient liquids -

Coatings & Materials Industry

Paints, resins, functional liquid materials

Suitable Containers

-

Plastic drums (10–30L)

-

Metal drums (10–30L)

-

Square or round containers within 30L capacity

Extended Product Description

The Large Drum Weighing Filling Machine is engineered for medium-capacity drum filling applications up to 30 liters, bridging the gap between small bottle fillers and large barrel filling systems.

By utilizing an independent weighing platform and closed-loop feedback control, the machine delivers highly accurate and repeatable filling results, even for products with varying viscosity or density.

Advanced Working Principle

-

Empty drums are placed onto the weighing platform.

-

The system automatically performs tare weight calibration.

-

Filling begins with fast filling to reach most of the target weight.

-

The system switches to slow fine filling based on real-time weight feedback.

-

Filling stops automatically once the preset weight is reached.

-

Filled drums are discharged for capping or sealing.

This two-stage filling logic ensures both high speed and high accuracy.

Operational & User Benefits

-

Minimal operator intervention after parameter setup

-

Recipe storage for different products and drum sizes (up to 30L)

-

Quick changeover for different filling weights

-

Lower labor intensity and reduced operator error

-

Easy maintenance with modular component design

Safety & Reliability

-

Overflow protection system

-

Emergency stop and alarm functions

-

Leakage detection options

-

Stable mechanical frame designed for long-term operation

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.