Product Introduction

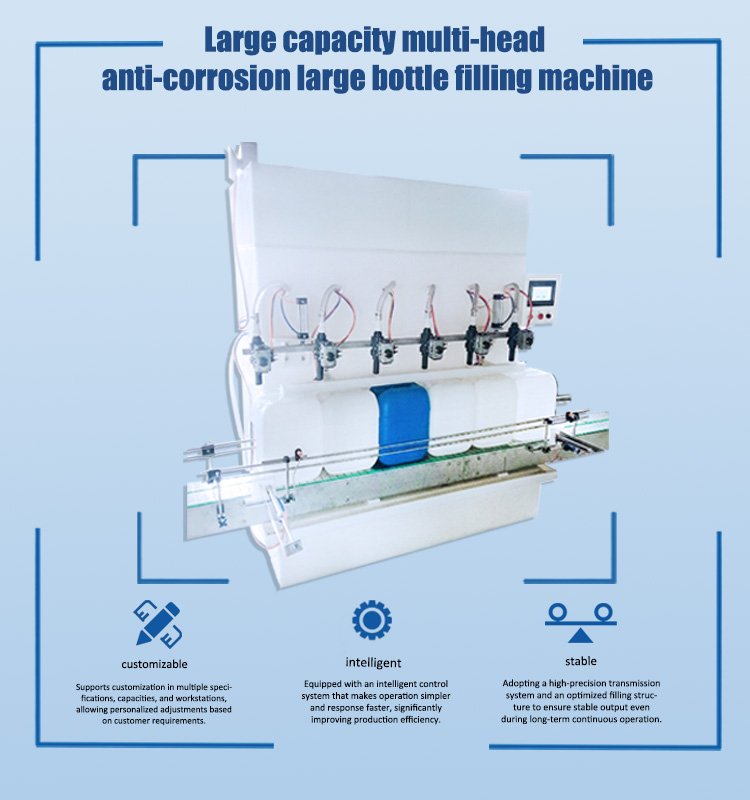

The Large Capacity Multi-Head Anti-Corrosion Large Bottle Filling Machine is specially designed for efficient and precise filling of corrosive and non-corrosive liquids into large-volume containers. With a robust anti-corrosion structure and multiple filling heads, this machine ensures high productivity, stable operation, and long service life.

It is widely used in chemical, daily chemical, pharmaceutical, and industrial liquid industries, especially for products with strong acidity or alkalinity.

Key Features

-

Multi-Head High-Efficiency Filling

Multiple filling nozzles operate simultaneously, significantly improving filling speed and output. -

Large Capacity Filling Design

Specifically engineered for large bottles, drums, and containers, suitable for high-volume liquid packaging. -

Anti-Corrosion Structure

Key contact parts are made of corrosion-resistant materials such as PP, PTFE, or SUS316, ensuring durability and safety when filling corrosive liquids. -

High Filling Accuracy

Advanced filling control system ensures precise volume control and stable filling performance. -

Fully Automatic Operation

Automatic bottle positioning, filling, and discharge reduce manual labor and improve production consistency. -

User-Friendly Control System

PLC control with touchscreen interface for easy parameter setting and quick product changeover.

Key Selling Points

-

Designed for corrosive liquids such as acids and alkalis

-

High output capacity with multi-head simultaneous filling

-

Compatible with large-volume containers

-

Strong and durable anti-corrosion materials

-

Low maintenance and long service life

-

Easy integration into automated filling lines

Applicable Industries & Examples

-

Chemical Industry

Examples: Hydrochloric acid, sulfuric acid, sodium hypochlorite, chemical solvents -

Daily Chemical Industry

Examples: Bleach, toilet cleaner, disinfectant, descaling liquid -

Pharmaceutical & Healthcare Industry

Examples: Disinfectant solutions, laboratory reagents (with compliant configurations) -

Industrial Liquids

Examples: Industrial cleaning agents, rust removers, water treatment chemicals

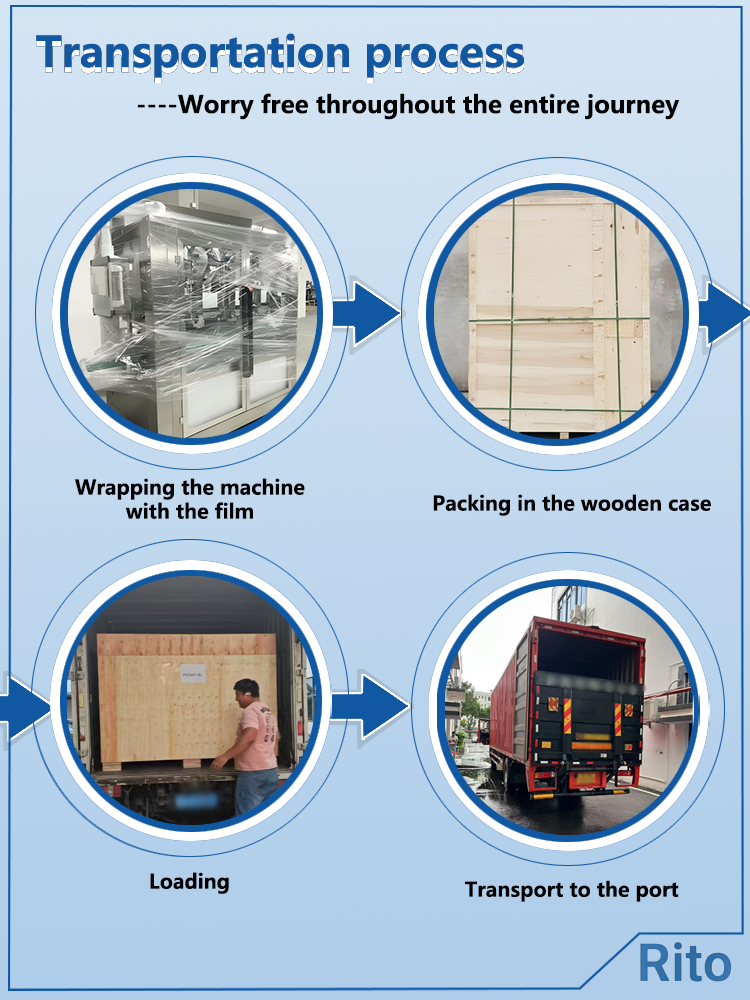

The Large Capacity Multi-Head Anti-Corrosion Large Bottle Filling Machine is an industrial-grade filling solution developed for high-volume, corrosive, and aggressive liquids.

The machine is engineered with a reinforced frame and corrosion-resistant components to ensure long-term stability, safety, and accuracy under harsh working conditions.

Designed for large bottles, jerry cans, and chemical drums, this system supports continuous operation and can be seamlessly integrated into fully automatic filling lines.

Advanced Structural Design

-

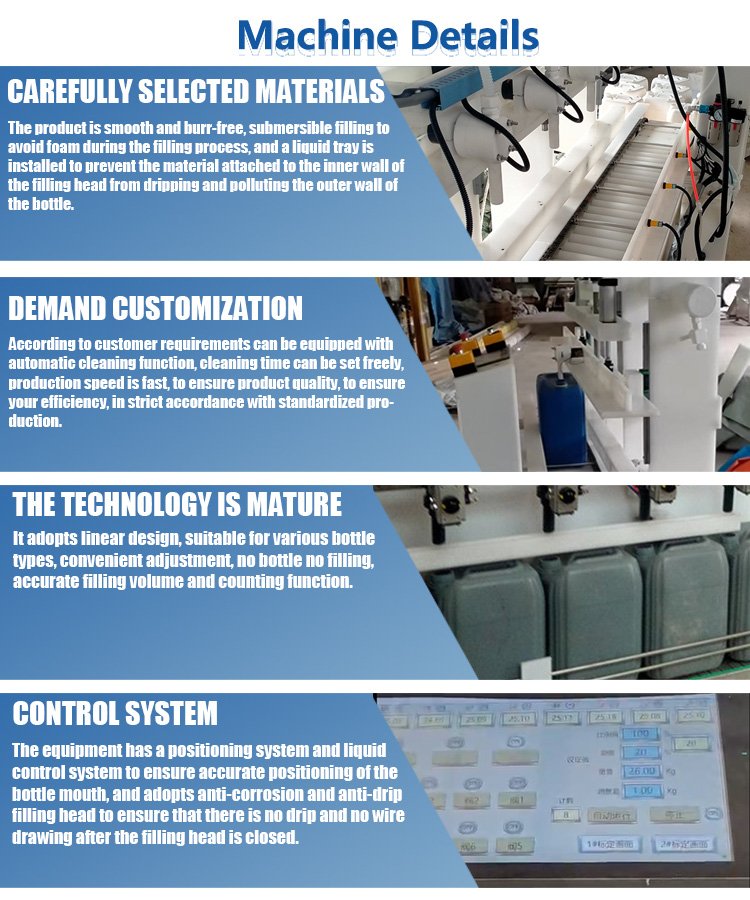

Full anti-corrosion design: All liquid-contact parts are made of PP, PTFE, or SUS316L, effectively resisting strong acids, alkalis, and chemical solvents.

-

Separated electrical and liquid zones: Prevents corrosion damage to electrical components and extends equipment lifespan.

-

High-rigidity frame structure: Minimizes vibration during filling, ensuring consistent accuracy even at high flow rates.

Filling Technology & Performance

-

Multiple filling methods available

-

Gravity filling

-

Time-controlled filling

-

Flow meter filling (optional)

-

-

High-flow filling system

Specially designed for large-capacity containers, enabling fast filling while preventing splashing and foaming. -

Bottom-up filling option

Reduces bubbles and improves filling quality for reactive liquids. -

Anti-drip & anti-splash nozzles

Ensure clean bottle mouths and safe operation.

Intelligent Control & Operation

-

PLC + touchscreen HMI

Simple operation, real-time monitoring, and fault alarm display. -

Recipe memory function

Quickly switch between different products and container sizes. -

Automatic error detection

Includes no-bottle-no-filling, overflow protection, and emergency stop systems.

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.