Machine Introduction

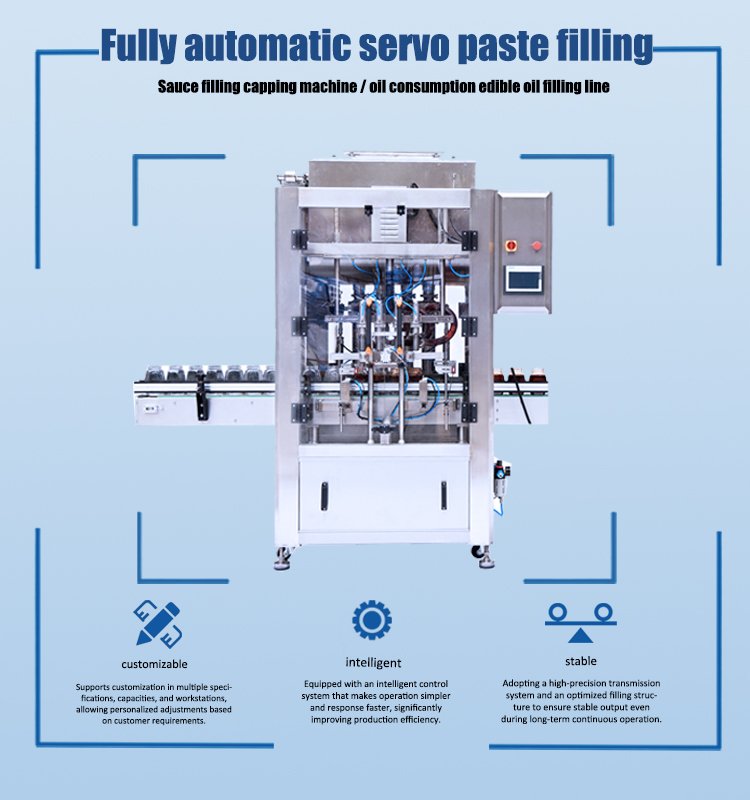

The Fully Automatic Servo Piston Paste & Liquid Filling Machine is a high-precision filling solution integrating automatic bottle infeed (or manual placement), accurate positioning, quantitative filling, and finished product discharge into one system. The machine adopts servo motor drive combined with a PLC intelligent control system, ensuring stable operation and highly accurate filling performance.

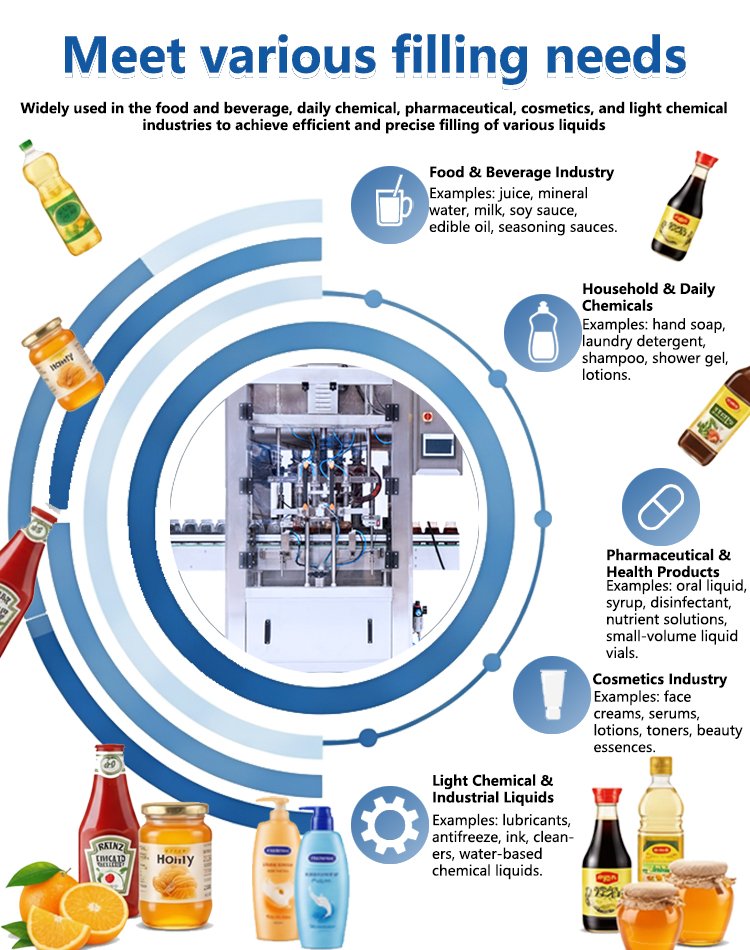

This machine is suitable for a wide range of liquids and pastes with different viscosities. With a compact structure, user-friendly HMI, and flexible configuration options, it can be customized in terms of filling heads, filling volume range, and auxiliary modules to meet different production requirements. It is widely used in food, daily chemical, pharmaceutical, and chemical industries.

Main Features

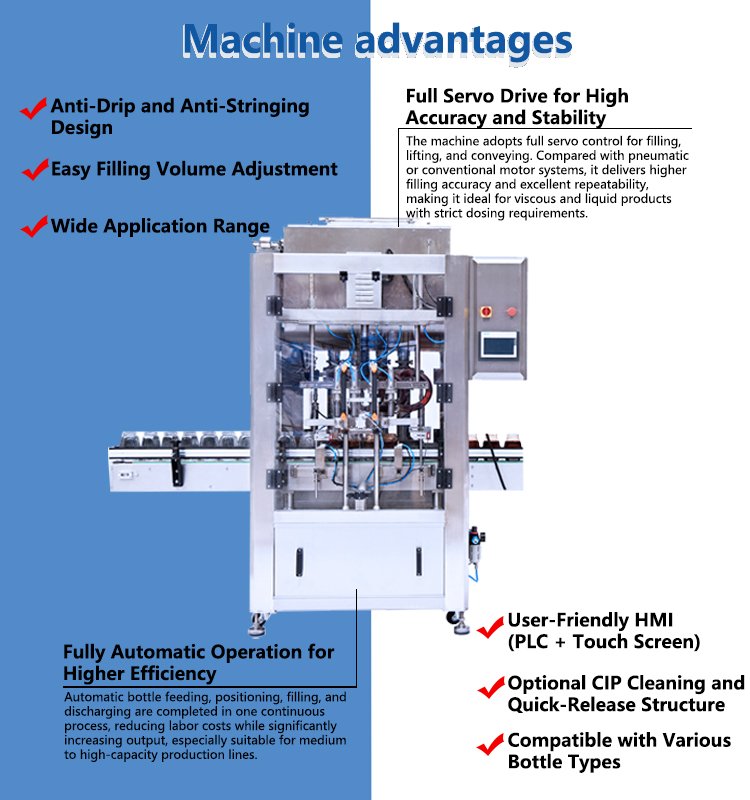

- Servo Motor Driven, High Accuracy

The filling system is controlled by a servo motor driving pistons or screw mechanisms. Filling volume is set directly on the touchscreen, ensuring high repeatability and minimal error. - Wide Application Range

Suitable for liquids, semi-fluids, and high-viscosity pastes such as sauces, creams, gels, and lotions, with excellent material adaptability. - Fully Automatic Operation

Automatically completes bottle feeding, positioning, filling, and discharging, significantly reducing labor costs and improving production efficiency. - Easy Operation & Maintenance

PLC + touchscreen control makes parameter adjustment simple and fast. Product-contact parts are easy to disassemble and clean, meeting hygiene requirements. - Stable Structure & Reliable Performance

The frame is made of high-quality stainless steel and reinforced materials, ensuring stable operation and suitability for long-term continuous production. - Highly Customizable

Machine configuration can be tailored according to bottle types, filling volumes, production capacity, and production line layout.

Key Selling Points

- High Filling Precision: Servo control ensures consistent filling volume for every bottle, reducing product waste.

- High Production Efficiency: Multi-head simultaneous filling meets medium to high output demands.

- Intelligent Control System: Multiple recipes can be stored and switched with one touch.

- Hygienic & Safe Design: Food-grade and pharmaceutical-grade materials are available to comply with industry standards.

- High Return on Investment: Reduces dependence on labor while improving overall automation level of the production line.

Detailed Technical Description

-

Filling System

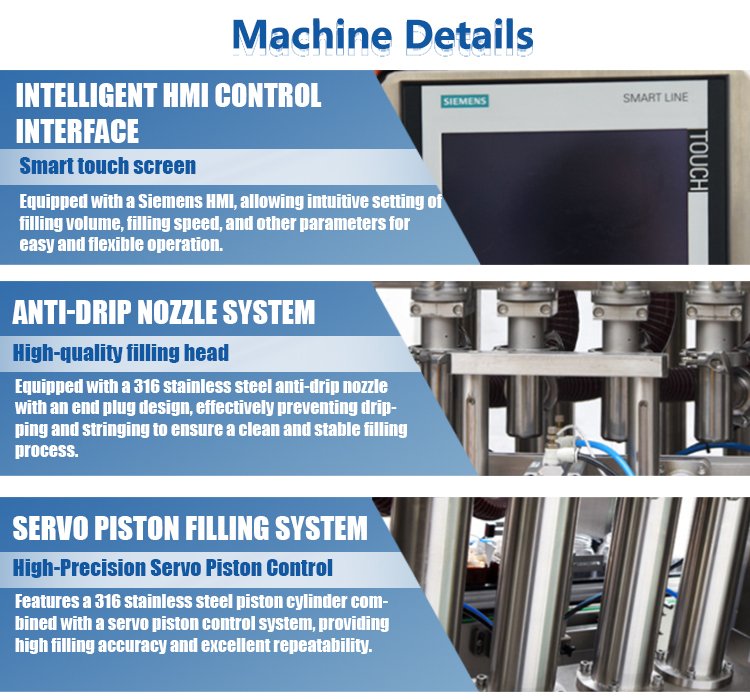

The machine adopts a servo-driven piston filling system (or optional servo screw filling system), ensuring precise and stable filling performance.

-

Control System

Equipped with a PLC control system and HMI touchscreen interface, the machine offers intuitive operation and real-time monitoring. Operators can easily set filling volume, filling speed, and production parameters.

-

Mechanical Structure

The machine frame is manufactured from SUS304 stainless steel, with SUS316L optional for product-contact parts to meet higher hygiene requirements.

-

Hygiene & Safety Design

All product-contact components are made of food-grade or pharmaceutical-grade materials and comply with GMP standards. The filling system supports quick disassembly for cleaning and maintenance, reducing the risk of cross-contamination.

Optional Configurations

- Number of filling heads: 4 / 6 / 8 / 10 / 12 / 16 or customized

- Automatic bottle infeed system

- Servo-controlled capping or sealing system

- Hopper with heating, mixing, or level control

- CIP cleaning system

- Nitrogen filling system

- Customized filling nozzles according to product characteristics

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.