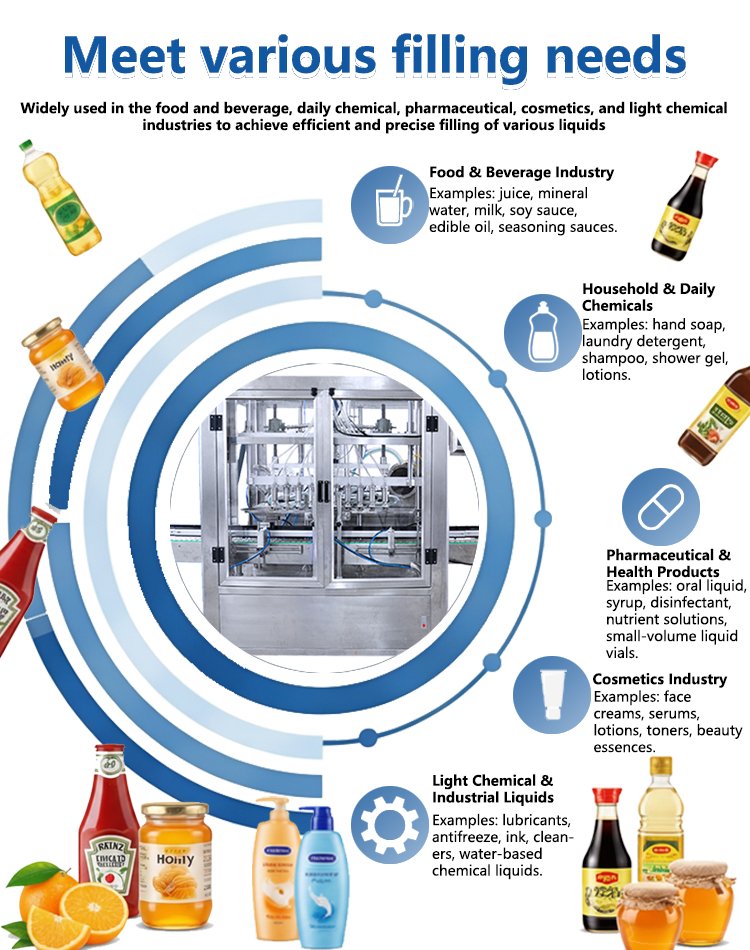

The fully automatic gravity liquid filling machine is designed for low-to-medium viscosity liquids, widely used in food, beverage, cosmetics, pharmaceutical, and chemical industries. Utilizing a gravity-flow filling principle combined with precise flow control, this machine ensures high-speed, accurate filling while being easy to operate and maintain. It is an ideal solution for modern production lines seeking efficiency and reliability.

Key Features

-

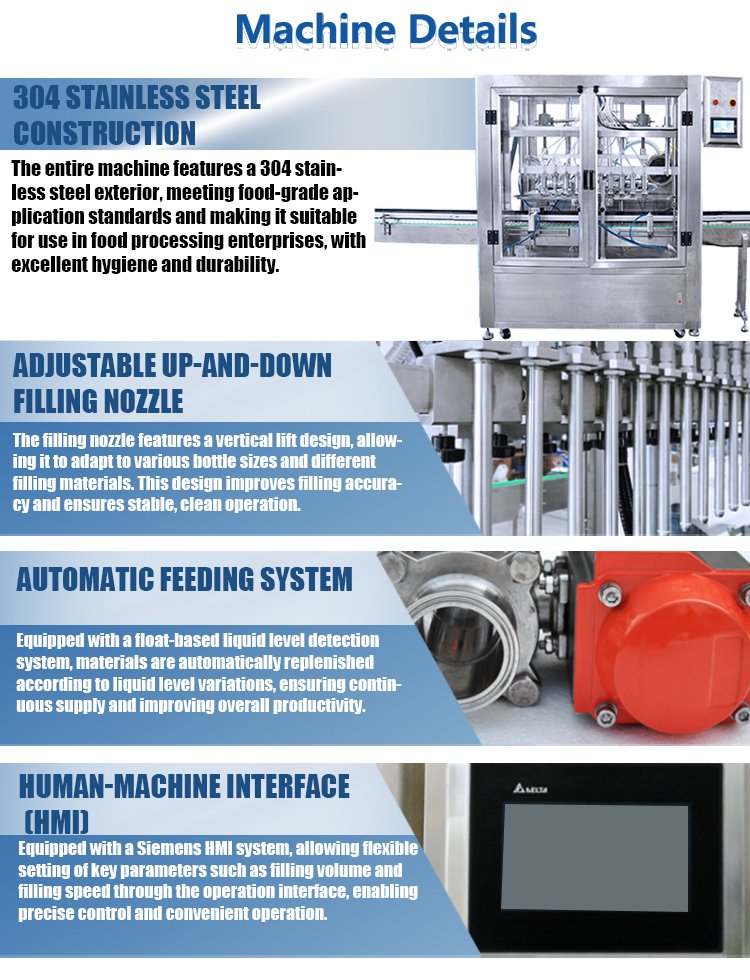

Fully Automatic Control

Equipped with an advanced PLC system and touchscreen Human-Machine Interface (HMI), allowing flexible setting of filling volume, speed, and intervals for precise, intelligent operation. -

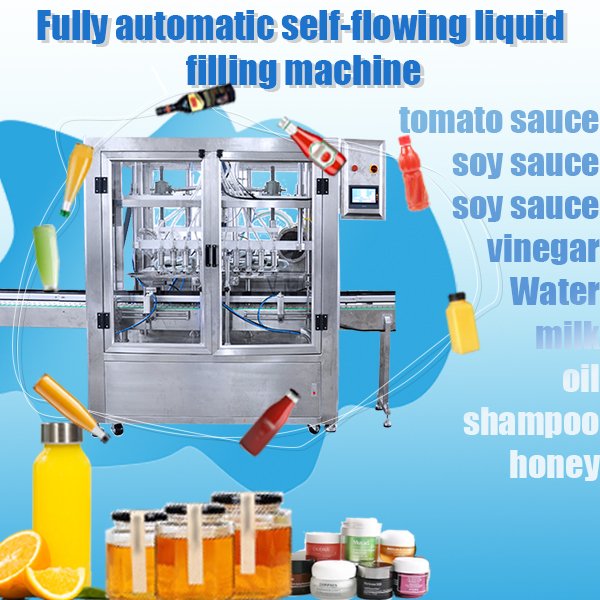

Gravity Flow Filling Technology

Smooth filling process with minimal dripping, controlled by electromagnetic or pneumatic valves. Suitable for water, juice, soy sauce, detergents, and other low-to-medium viscosity liquids. -

Multi-Head Design for High Efficiency

Configurable with 1 to 16 filling heads, enabling simultaneous operation to significantly increase production capacity for batch processing. -

High Accuracy and Stability

Each fill is precisely controlled with a deviation of less than ±1%, ensuring consistent product quality and minimizing waste. -

Hygienic and Safe Design

All liquid-contact parts are made of stainless steel, meeting food and pharmaceutical hygiene standards. Components are easy to disassemble and clean, reducing cross-contamination risks. -

Versatile Adaptability

Compatible with various bottle shapes and container sizes. Supports timed filling, continuous filling, and batch filling modes to meet different production needs.

Core Selling Points

-

High Efficiency: Multi-head design and automated control increase production speed and reduce labor costs.

-

Precision & Consistency: Accurate filling reduces waste and ensures product uniformity.

-

User-Friendly Operation: Touchscreen HMI allows quick parameter settings and adjustments.

-

Hygienic & Safe: Stainless steel construction and easy-to-clean design comply with food and pharmaceutical standards.

-

Flexible Application: Suitable for a wide range of liquids and container types across multiple industries.

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.