Introduction

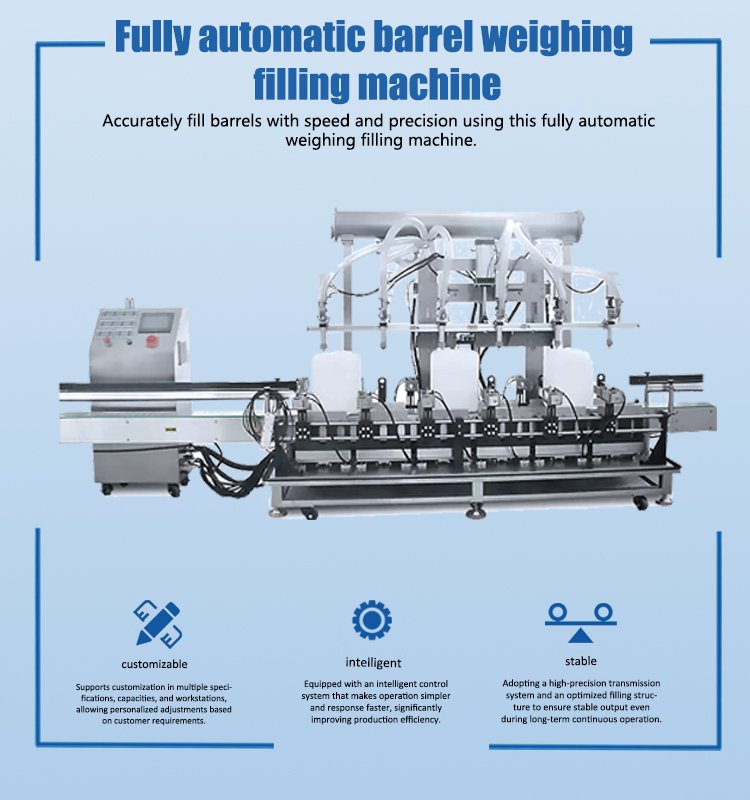

The Fully Automatic Barrel Weighing and Filling Machine is a high-efficiency device specially designed for large-capacity liquids, pastes, or granular materials. It is widely used in food, chemical, pharmaceutical, and daily chemical industries.

This machine integrates automatic barrel loading, weighing, filling, and unloading into one system. Equipped with an advanced electronic weighing system, it ensures precise quantitative filling for each barrel, achieving high productivity and easy operation.

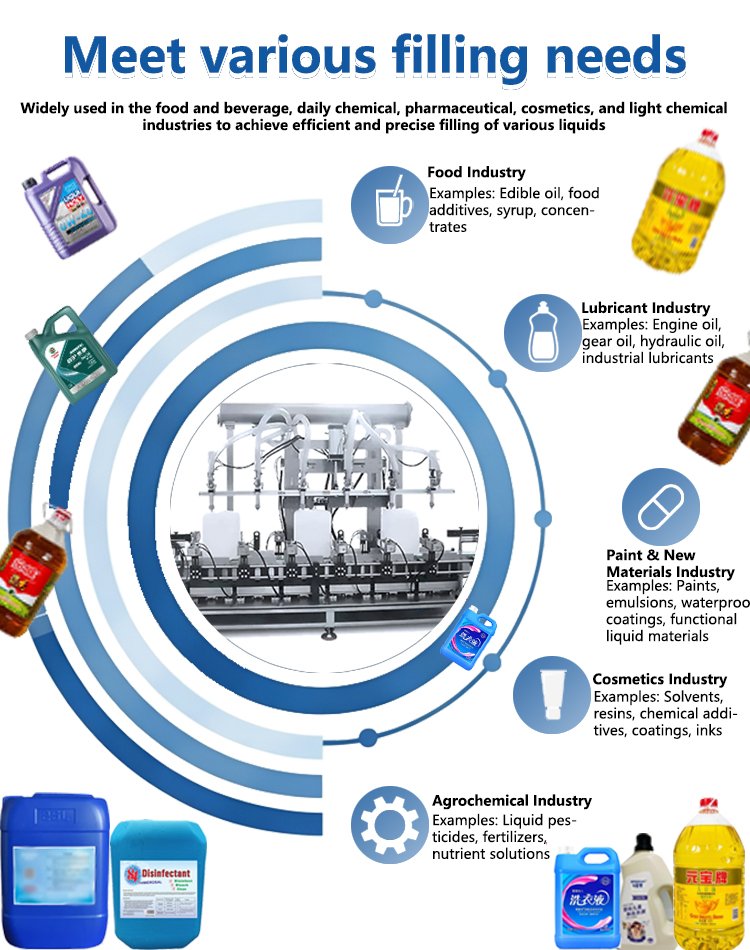

Applicable materials: liquids, beverages, oils, chemical liquids, detergents, jams, honey, dairy products, and more.

Key Features

-

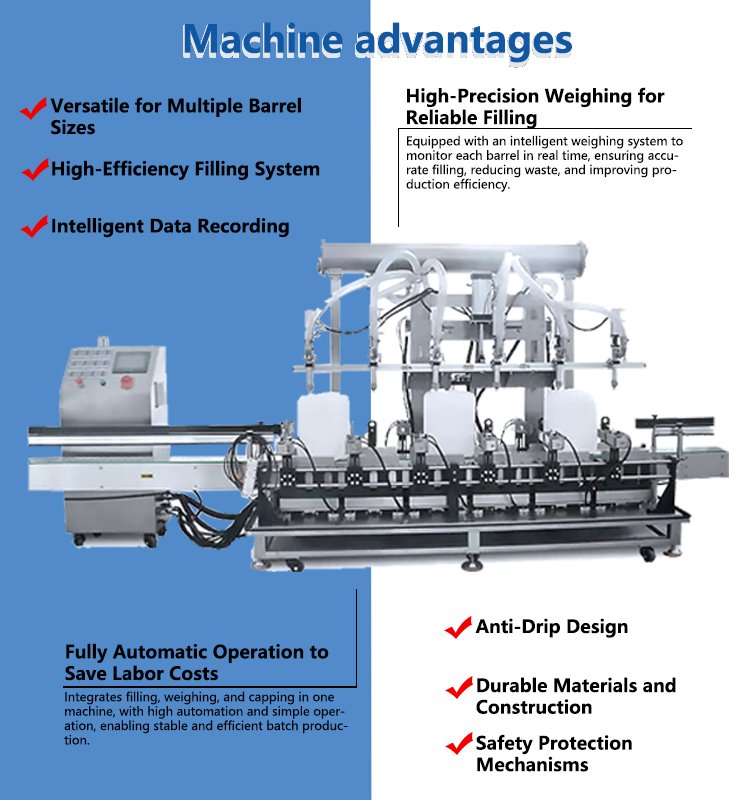

Fully Automated Operation

-

Automatic barrel loading, filling, unloading, and capping, reducing labor and increasing production efficiency.

-

-

High-Precision Weighing & Filling

-

Equipped with high-precision electronic scales or load cells, achieving filling accuracy within ±0.2% for consistent product weight.

-

-

Versatile for Multiple Barrel Sizes

-

Automatically adjusts filling volume for barrels of different capacities (e.g., 5L, 10L, 20L, 25L) without changing parts.

-

-

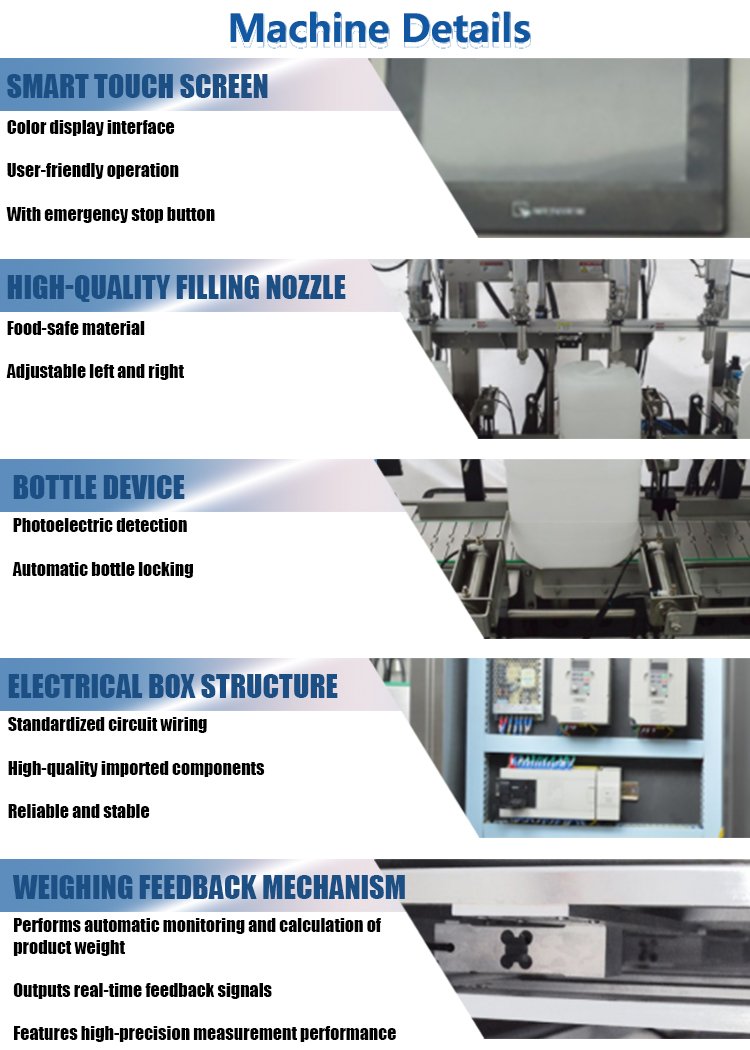

Intelligent Control System

-

PLC or touch screen interface for user-friendly operation, real-time display of filling weight, speed, and error alarms.

-

-

Efficient and Energy-Saving Design

-

Uses variable frequency motor control and automatic measurement system to reduce material waste and energy consumption.

-

-

Hygienic & Easy to Clean

-

SUS304 stainless steel contact parts and machine body comply with food and chemical hygiene standards, simplifying cleaning and maintenance.

-

-

Safe and Reliable

-

Multiple safety protections, including anti-leakage, overflow prevention, and emergency stop functions, ensuring operational safety.

-

Core Selling Points

-

Boost Productivity: Fully automated operation significantly improves filling efficiency for large-scale production.

-

Precise Measurement: Weighing-based filling ensures uniform barrel weight, reducing complaints and material loss.

-

Flexible Adaptability: Supports multiple barrel types and capacities.

-

Easy Operation: Intelligent control system requires minimal training.

-

Hygienic Design: Stainless steel construction meets food and chemical industry standards.

-

Cost-Effective: Reduces labor and material waste, improving overall profitability.

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.