Product Overview

The Fully Automatic 16-Head Piston Filling Machine is designed for high-speed, high-precision filling of liquid and semi-viscous products. Equipped with 16 simultaneous piston filling heads, this machine offers large production capacity, stable operation, and excellent accuracy, making it ideal for medium to large-scale production lines.

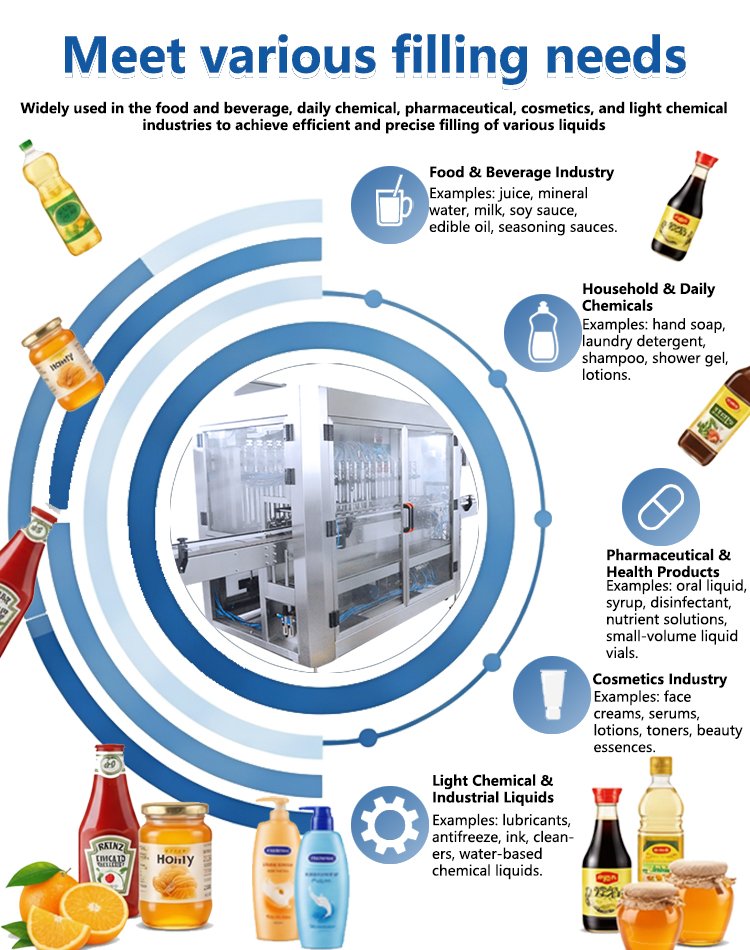

It is suitable for industries such as food, daily chemicals, pharmaceuticals, chemicals, and agrochemicals.

Key Features

-

16-Head High-Speed Filling

-

Enables simultaneous filling of 16 bottles, greatly increasing production efficiency.

-

-

Piston Filling Mechanism

-

Suitable for liquids of medium to high viscosity, ensuring precise measurement without foaming or dripping.

-

-

Fully Automatic Operation

-

Integrates bottle positioning, filling, and discharge, reducing labor costs and human error.

-

-

High Filling Accuracy

-

Advanced servo-controlled pistons provide consistent volume for each container, minimizing material waste.

-

-

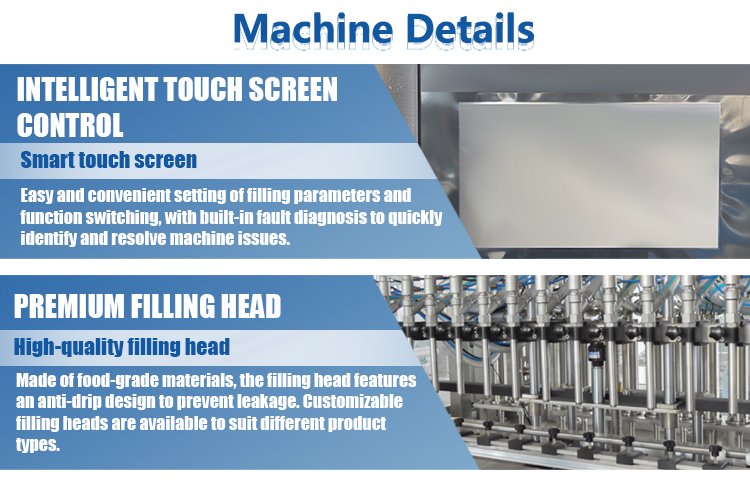

User-Friendly Control System

-

PLC + Touchscreen interface for easy parameter adjustment and fast product changeover.

-

-

Hygienic and Durable Structure

-

Stainless steel construction (SUS304/SUS316 optional), easy to clean, compliant with food and pharmaceutical standards.

-

-

Flexible Container Compatibility

-

Adjustable for various bottle heights, diameters, and shapes.

-

Key Selling Points

-

High Productivity: 16 heads for fast, large-scale production.

-

Precise and Stable: Accurate piston filling reduces overfill and product loss.

-

Versatile Application: Works with viscous liquids, pastes, and creams.

-

Easy Operation: PLC control with intuitive touchscreen interface.

-

Seamless Integration: Can connect with bottle unscramblers, capping machines, and labeling lines.

Applications

1. Food Industry

-

Peanut butter, honey, tomato paste, jam, chocolate sauce, sauces

2. Daily Chemical Industry

-

Shampoo, conditioner, body lotion, toothpaste, hand cream

3. Pharmaceutical & Healthcare Industry

-

Medicinal gels, ointments, syrups (GMP-compliant)

4. Chemical Industry

-

Lubricating paste, adhesives, sealants, industrial chemicals

5. Agrochemical Industry

-

Liquid fertilizer, pesticide gels, plant nutrient compounds

Working Principle

The machine uses a piston-driven volumetric filling system:

-

The piston draws a pre-measured volume of liquid from the hopper.

-

The liquid is then injected into the container through the filling nozzle.

-

Sensors and PLC control monitor the piston movement and container position to ensure high precision and repeatability.

Key advantages of this system

-

Not affected by viscosity changes or foaming.

-

Reduces dripping and overflow.

-

Suitable for high-viscosity liquids, creams, gels, and pastes.

Features

Multi-Nozzle Customization: Adjustable nozzle spacing for different container widths.

Hot Filling Option: For high-temperature liquids.

Explosion-Proof Version: For flammable chemical liquids.

Integration with Filling Lines: Fully automated with conveyors, cappers, and labelers.

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.