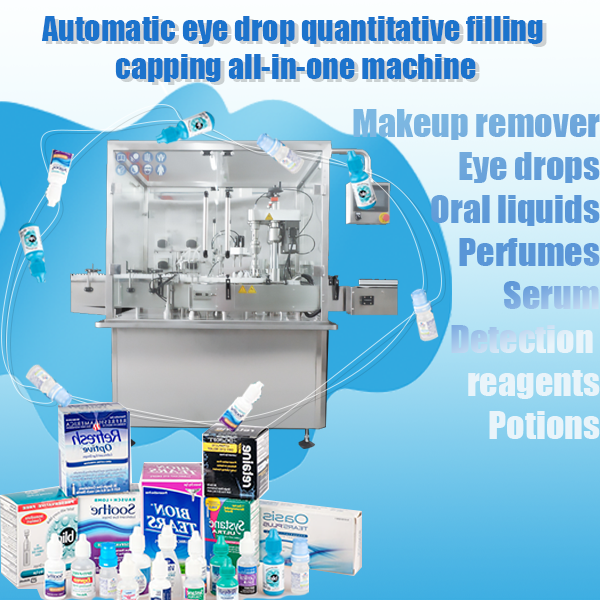

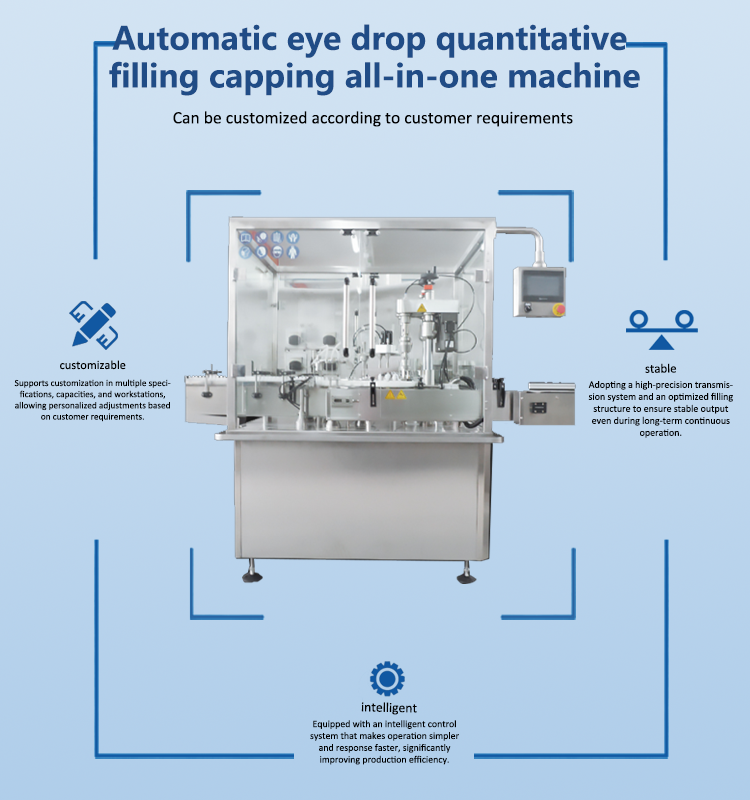

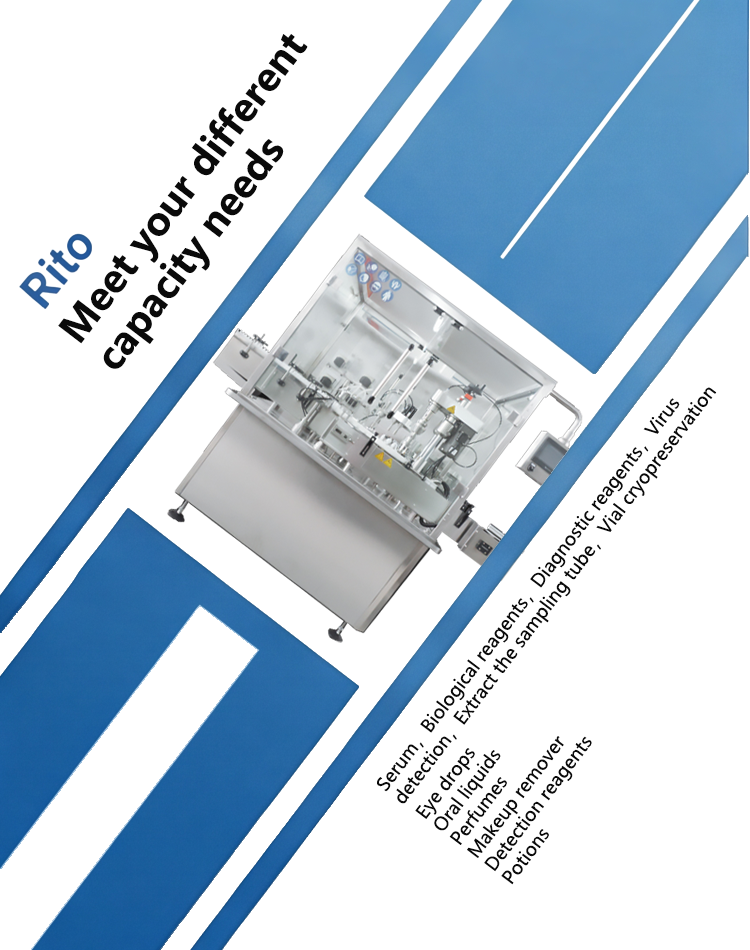

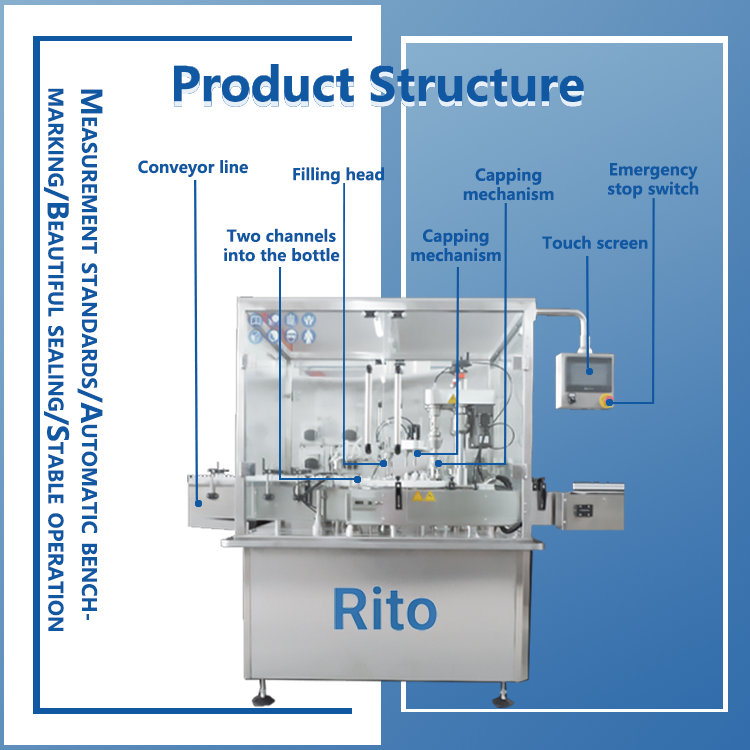

The Automatic Eye Drop Quantitative Filling Capping All-In-One Machine is an innovative and advanced device that significantly enhances the manufacturing of eye drop products. This machine is designed to accurately and efficiently fill the eye drop bottles with the right amount of liquid and seal the caps automatically. The technology used in this machine is the latest in the market and ensures high precision and consistency in every production.

One of the most significant advantages of the Automatic Eye Drop Quantitative Filling Capping All-In-One Machine is that it saves time and effort for the manufacturers. The machine is fully automated and is capable of filling and capping hundreds of eye drop bottles in a minute without any errors. This means that the production capacity of the manufacturers is significantly enhanced, allowing them to meet the ever-increasing demand for eye drop products.

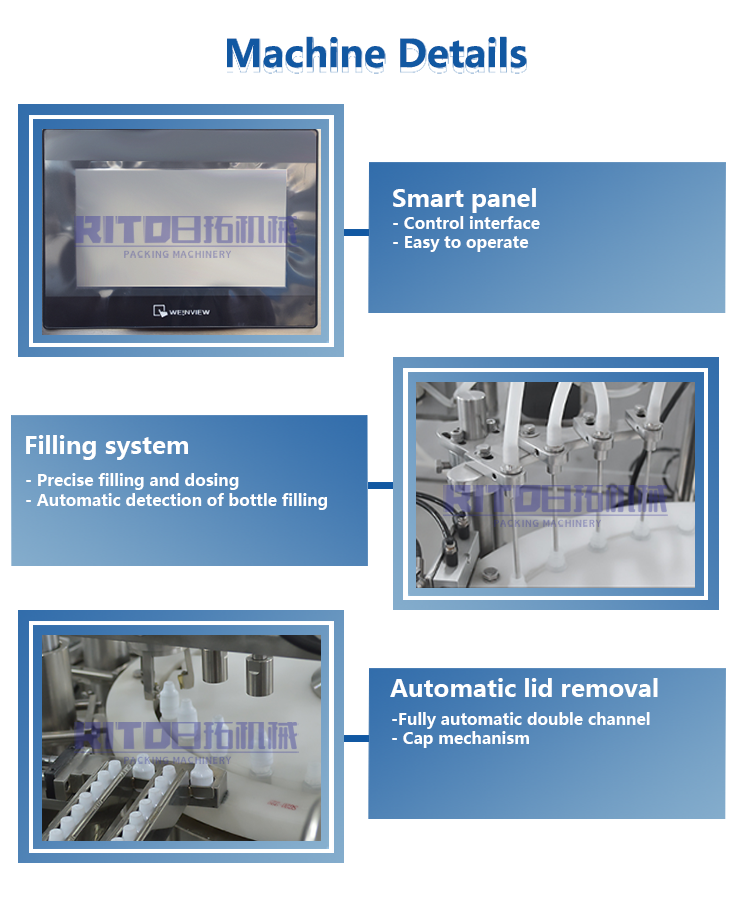

Another benefit of this machine is that it ensures high quality and safety of the eye drop products. The machine is designed with high-tech sensors that detect any inconsistencies or defects in the process and immediately alerts the operator. This feature ensures that the products manufactured are of the highest quality and meet the required safety standards.

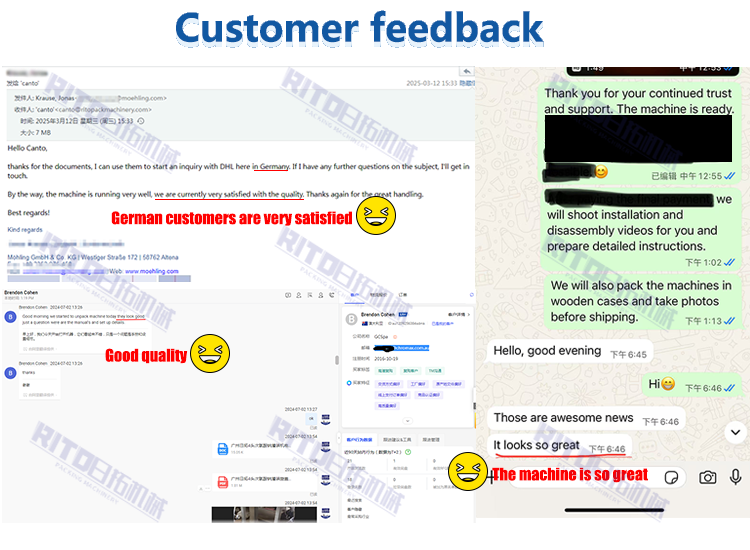

The Automatic Eye Drop Quantitative Filling Capping All-In-One Machine is an excellent investment for the manufacturers who want to streamline their production process and increase their production capacity. With its advanced technology, high precision, and consistent performance, this machine offers numerous benefits that can help the manufacturers to stay ahead of their competitors in the market.

In conclusion, the Automatic Eye Drop Quantitative Filling Capping All-In-One Machine is a highly advanced and innovative device that enhances the manufacturing of eye drop products. The positive impact of this machine on the production process, quality, and safety of the products makes it an excellent investment for the manufacturers who are looking to boost their production capacity and stay ahead in the market.

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.