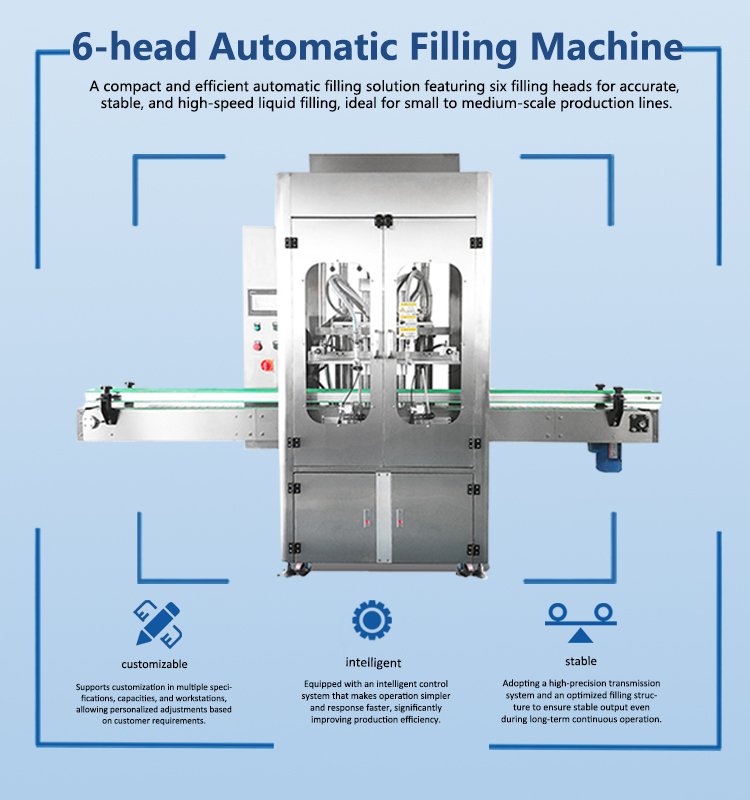

Key Features:

6 filling heads operating simultaneously for higher productivity.

PLC control system with intuitive parameter setting.

High filling accuracy with stable and repeatable results.

Automatic bottle feeding, filling, and discharging.

Compatible with different bottle sizes and shapes.

Selling Points:

-

⚙️ Efficient & Cost-Effective: Ideal balance between output and investment

-

🎯 Precision Filling: Accurate volume control with minimal product loss

-

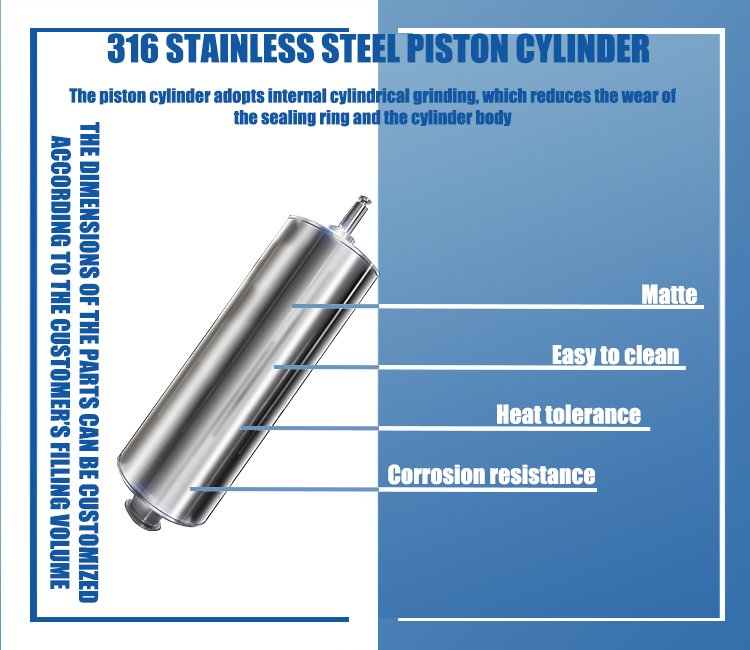

🧩 Customizable Design: Parts and filling volume can be customized according to customer requirements

-

🔗 Easy Line Integration: Can be connected with conveyors, capping, labeling, and coding machines

-

🛡️ Durable Structure: Built with high-quality components for long-term operation

Applications:

The 6-head automatic filling machine is widely applied across multiple industries and is suitable for filling liquid and semi-liquid products with different viscosities. It can handle various container types, including round bottles, square bottles, and irregular-shaped containers.

Food & Beverage Industry

Ideal for filling sauces, edible oils, beverages, syrups, honey, dairy products, and other food-grade liquids. The machine ensures hygienic operation, stable filling accuracy, and smooth production flow, meeting food production requirements.

Cosmetics & Personal Care Industry

Suitable for lotions, creams, shampoos, conditioners, liquid soaps, and cosmetic liquids. It provides precise volume control and consistent appearance, helping brands maintain product quality and packaging consistency.

Chemical Industry

Widely used for detergents, cleaning agents, disinfectants, lubricants, and other chemical liquids. The machine can be designed with anti-corrosion materials to ensure long-term durability and safe operation.

Pharmaceutical & Healthcare Industry

Applicable for oral liquids, medical solutions, disinfectants, and healthcare liquids. Stable and accurate filling performance helps meet pharmaceutical production standards.

Packaging Flexibility

The machine supports different bottle sizes, filling volumes, and production requirements. It can be integrated into a fully automated filling line with conveyors, capping, labeling, and coding machines, making it suitable for both small-scale and large-scale production.

1. Material tank, filling nozzle and the parts access to liquid are made of #304 stainless steel and PVC used in food industry.

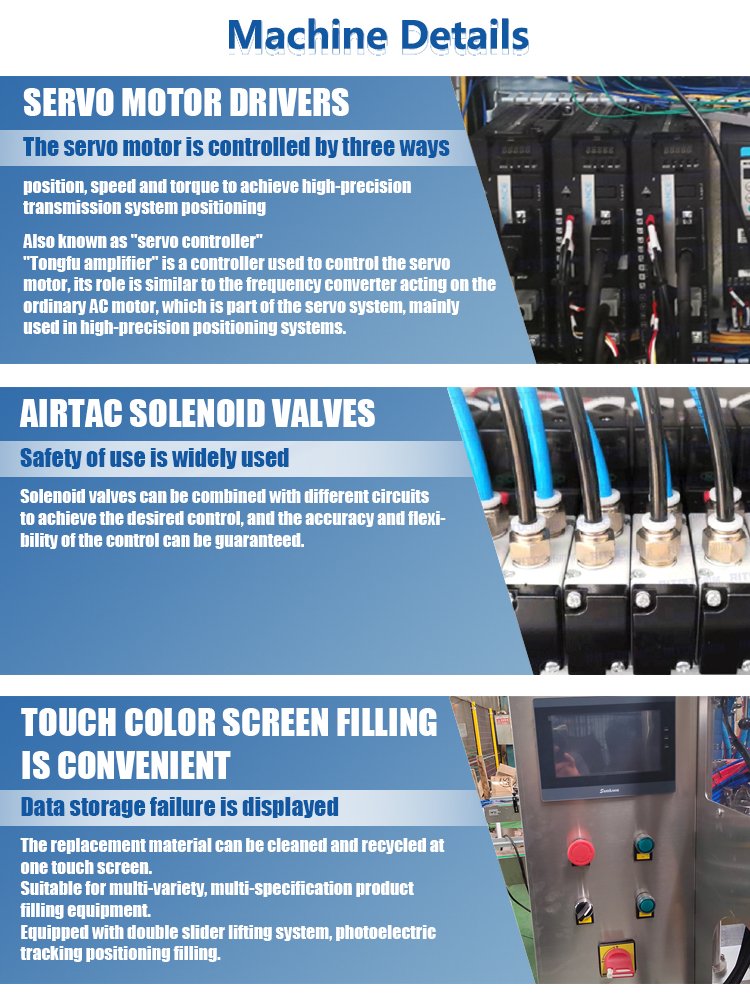

2. Pneumatic components: AIRTAC of Taiwan.

3. PLC: Siemens of Germany.

4. HMI: 7″color touch screen of Siemens of Germany.

5. Photoelectric sensor LEUZE in Germany or SICK of Germany.

6. Relay and air switch: Schneider of France.

7. Material pumping: Domestic stainless steel gear pump.

8. Motor frequency converter: AB of the United States, Schneider of France or Siemens of Germany.

9. Conveyer belt material: Stainless steel chain belt with a width of 82mm.

10. Conveyer belt motor: Domestic AC motor.

11. Materials of the seal ring of the sealing machine: silicone, fluorine rubber, polytetrafluoroethylene.

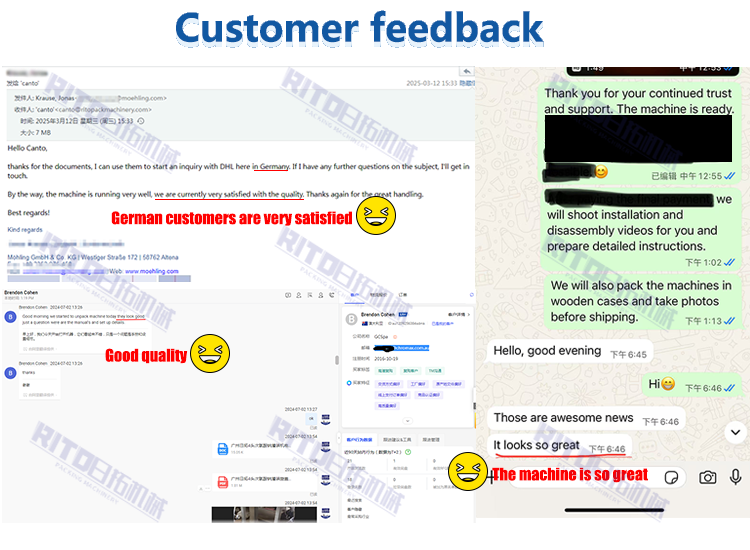

The Guangzhou headquarters occupies an area of 3000 square meters. It is a national high-tech enterprise integrating R&D, production, sales and service of packaging machinery. It is a high-tech enterprise supported by the Guangzhou Municipal Government.

Since its establishment, Guangzhou RITO packaging machine co.,Ltd has been committed to becoming a world-class packaging machinery company, attaching importance to product development and innovation, insisting on independent research and development of product lines, and having a top technology research and development team with more than 20 years of experience in the packaging machinery field. Including software engineers, mechanical engineers, electrical engineers, industrial designers, etc., they have made outstanding contributions in the fields of outlook design, software development, and mechanical design. Our products has more than 10 patents, of which more than 1/2 are invention patents. Far ahead of the industry.

Based on the needs of customers in various industries and the in-depth cultivation of the terminal market, Guangzhou RITO packaging machine co.,Ltd has launched piston liquid filling machine, capping machine, labeling machine, and Back end packaging machine with its strong R&D capabilities in the field of packaging machine marking and many years of industry accumulation. Industry application solutions liquid filling machine series, capping machine series, labeling machine series and other back end carton packing machines have been recognized and praised by many customers at home and abroad, and strive to have an impact on the Chinese manufacturing industry in the world.