Handling corrosive liquids1 is tough. Your equipment fails, production stops, and costs soar. But you can avoid these issues by learning the most common mistakes people make.

The biggest mistakes are using incompatible materials, neglecting anti-drip features2, and sticking with manual systems3. To avoid them, choose corrosion-resistant machinery4 with proper seals, anti-drip nozzles, and automation5 to ensure safety, accuracy, and efficiency in your production line.

Filling corrosive products like acids, bleach, or certain chemicals presents unique challenges. A small mistake doesn't just lead to a little waste; it can destroy your equipment, compromise worker safety, and bring your entire operation to a halt. Over my 20+ years in the packaging machinery field, I’ve seen companies struggle with these exact issues. The good news is that these problems are almost always preventable. It starts with understanding the pitfalls and knowing what to look for in a filling solution6. Let’s break down the most critical mistakes I see and, more importantly, how you can avoid them for good.

Is Using the Wrong Material the Biggest Mistake in Corrosive Liquid Filling?

Your filling machine is failing and you don't know why. Leaks, rust, and constant breakdowns are costing you time and money, turning a simple process into a major headache.

Yes, using the wrong material is a critical error. Standard metals and plastics degrade quickly when exposed to acids or alkalis. You must use machines built from corrosion-resistant materials, like 316L stainless steel7 or specialized polymers, to ensure longevity and prevent contamination.

When we talk about machine failure, the root cause is often a simple mismatch between the machine's material and the product's chemical properties. I remember a client who came to us after their new filling machine failed in under six months. They were filling a strong cleaning agent, and the standard-grade steel components were literally dissolving. This is a classic example of what happens when material compatibility is overlooked.

The Chemical Reaction Breakdown

Corrosive liquids, by their nature, react with other materials. Acids can oxidize metals, causing rust and degradation. Alkalis can be just as destructive, especially to certain plastics and seals. This isn't just about surface rust; it's about structural integrity. When a component degrades, it can lead to inaccurate fills, leaks that damage other parts of the machine, and potential product contamination8. Choosing the right material from the start is not an upgrade; it's a fundamental requirement.

Material Compatibility for Corrosive Liquids

To make the right choice, you need to know your options. Different materials offer different levels of resistance.

| Material | Compatibility with Acids | Compatibility with Alkalis | Best Use Case |

|---|---|---|---|

| Standard Steel | Poor | Fair | Not recommended for corrosive liquids1. |

| 304 Stainless Steel | Fair | Good | Mildly corrosive products, food-grade applications. |

| 316L Stainless Steel | Good | Excellent | Most industrial chemicals, acids, and alkalis. |

| PVC/PE/Teflon | Excellent | Excellent | Highly specific and aggressive chemicals where metals fail. |

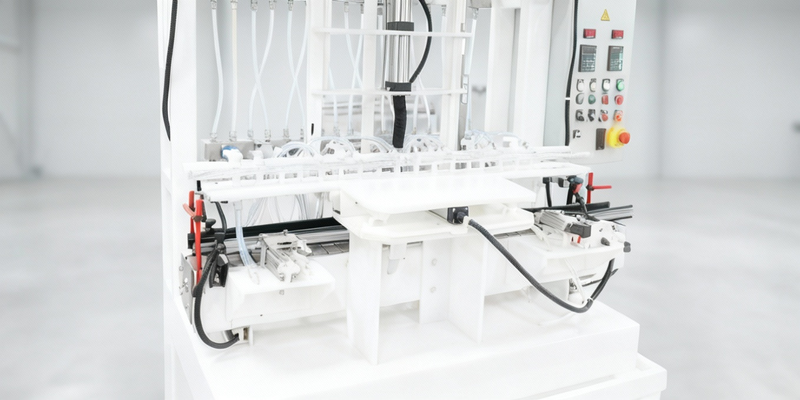

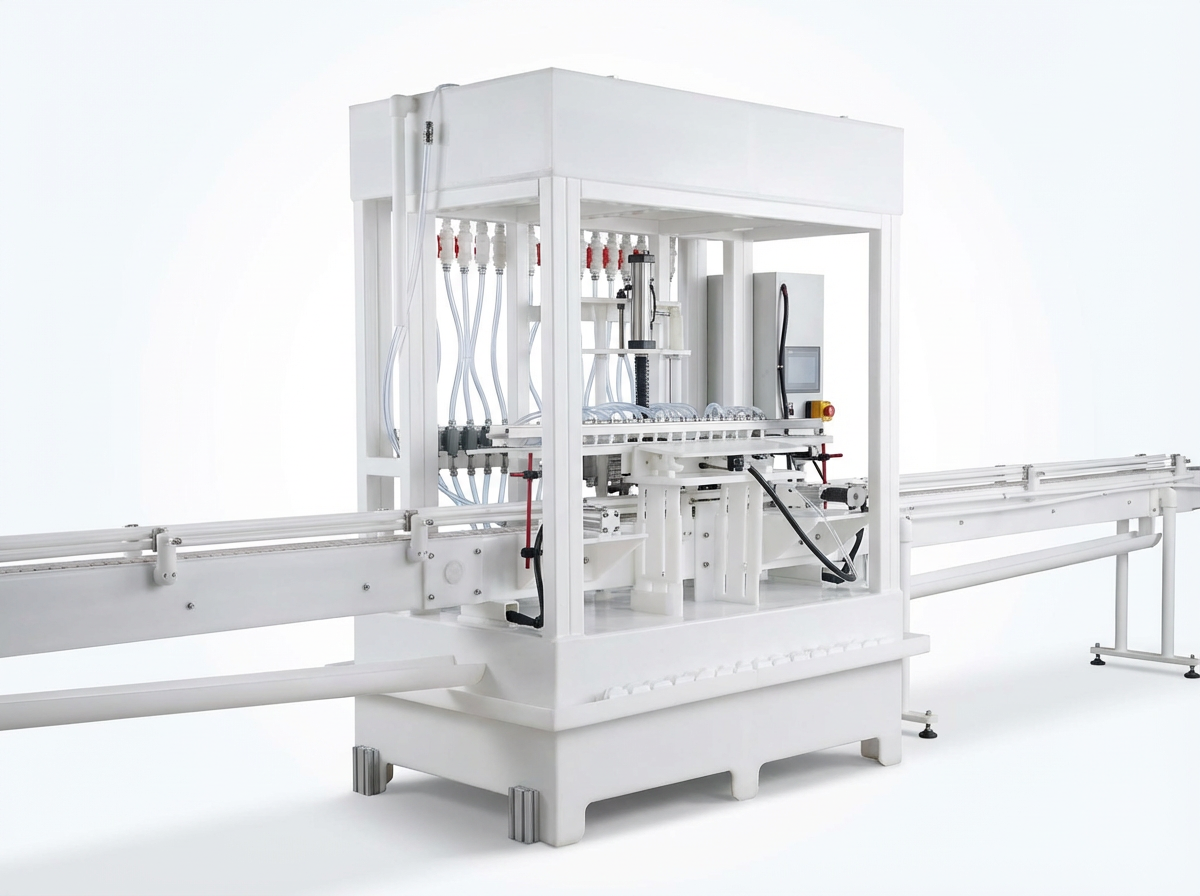

At RITO9, we build our piston filling machines with this in mind, often using 316L stainless steel7 for all contact parts to provide robust protection against a wide range of chemicals.

Why Do Anti-Drip Nozzles and Proper Seals Matter So Much?

You've got the right material, but your machine is still a mess. Constant drips are wasting product, corroding the machine's frame, and creating a hazardous work environment for your team.

Anti-drip nozzles and chemical-grade seals10 prevent costly product spillage and equipment damage. A single drip can corrode machine parts and create safety risks11. Proper design ensures a clean, safe, and efficient filling process, protecting both your investment and your operators.

A common belief is that a little dripping is just part of the process. I strongly disagree. Every drop of a corrosive liquid that lands where it shouldn't is a problem. It’s a direct loss of product, a safety hazard, and a maintenance issue waiting to happen. The solution lies in the small but critical details of the machine’s design: the nozzles and the seals.

The Domino Effect of a Single Drip

Imagine a single drop of an acidic solution landing on your machine's conveyor belt after every fill. At first, it's just a spot. Soon, that spot becomes a hole. The acid seeps into the conveyor's mechanics. It splashes onto the machine's frame, causing corrosion. Fumes can rise and affect sensitive electronic components like sensors. What started as one "insignificant" drip has now triggered a chain reaction of failures. This is why our R&D team at RITO9 focuses heavily on anti-drip technology. Our nozzles are designed with a positive shut-off mechanism that ensures a clean cut-off, every single time.

Sealing: The Unsung Hero of Filling

If the nozzle is the gatekeeper, the seals are the walls. Seals, like O-rings and gaskets12, are everywhere inside a filling machine, ensuring the liquid stays on its intended path. Standard rubber seals will quickly swell, crack, or dissolve when they meet corrosive chemicals. This leads to internal leaks that are often harder to detect until significant damage is done. For these applications, you need seals made from materials like Viton or Teflon13 (PTFE), which are specifically designed to withstand chemical attack. It’s a small component that makes a huge difference in reliability and long-term operating costs.

Could Underestimating Automation Be Limiting Your Production Capacity?

You rely on manual filling, thinking it saves money. But your output is slow, fill volumes14 are inconsistent, and you're worried about operator exposure to harsh chemicals.

Yes, underestimating automation5 is a major bottleneck. Manual filling is slow, inconsistent, and poses safety risks11. An automated system provides precise fill volumes14, increases production speed, and protects operators, delivering a much higher return on investment over time.

Many businesses, especially smaller ones, start with manual or semi-automatic filling to keep initial costs low. While this seems practical, it often becomes a major obstacle to growth. I once worked with a company in the agricultural sector producing a liquid fertilizer. They were filling by hand and could barely meet their daily orders. They thought a fully automated system would be too complicated and expensive.

The True Cost of Manual Filling

The "savings" from manual filling are often an illusion. The real costs are hidden in inefficiency and risk. First, there's inconsistency. A human operator can't guarantee the exact same fill volume every single time, leading to product giveaway or underfilled bottles. Second, speed is severely limited, putting a hard cap on your production capacity15. Finally, and most importantly, there is the safety risk. Direct, repeated handling of corrosive liquids1 is dangerous. An automated system encloses the process, protecting your team from spills and fumes.

Manual vs. Automated Corrosive Filling

The difference becomes clear when you compare the two approaches directly.

| Feature | Manual System | RITO9 Automated System |

|---|---|---|

| Fill Accuracy | Low & Inconsistent | High (e.g., within ±1%) |

| Production Speed | Low | High & Consistent |

| Operator Safety | Low (Direct Exposure) | High (Enclosed Process) |

| Long-Term ROI | Low (Waste, Labor, Limits) | High (Efficiency, Scalability) |

We showed that agricultural client how our automated piston filling machine, with its simple PLC control system16, could be operated by a single person after minimal training. Within the first week, they doubled their daily output and completely eliminated product spillage. Our strong R&D capability allows us to create stable, user-friendly systems17 that make automation5 an accessible and powerful tool for everyone.

Conclusion

Avoiding incompatible materials, poor design, and manual systems3 is key. The right corrosion-resistant, automated machine saves money, improves safety, and boosts your production line's efficiency from day one.

Understanding best practices can help you avoid costly mistakes and ensure safety when dealing with corrosive liquids. ↩

Discover how anti-drip features can prevent product loss and enhance safety in your filling operations. ↩

Learn about the limitations of manual systems and how they can hinder your production capacity. ↩

Learn about the benefits of using corrosion-resistant machinery to enhance the longevity and safety of your operations. ↩

Find out how automation can streamline your processes and significantly boost production efficiency. ↩

Identifying the right filling solution is crucial for safety and efficiency in handling corrosive liquids. ↩

Explore the unique properties of 316L stainless steel that make it ideal for corrosive environments. ↩

Understanding the causes of product contamination can help you implement better safety measures. ↩

Explore RITO's innovative solutions for corrosive liquid filling to enhance safety, efficiency, and reliability in your production line. ↩

Understanding chemical-grade seals can help you maintain equipment integrity and prevent leaks. ↩

Understanding safety risks is essential for protecting your workers and ensuring a safe work environment. ↩

Learn about the importance of O-rings and gaskets in maintaining the integrity of filling machines. ↩

Discover why Viton and Teflon are preferred materials for seals in corrosive environments. ↩

Learn techniques to achieve consistent and accurate fill volumes in your production line. ↩

Explore strategies to enhance production capacity and efficiency in your operations. ↩

Understanding PLC control systems can help you optimize automation in your filling processes. ↩

Discover the features that contribute to user-friendly systems, enhancing operator efficiency and safety. ↩